1980 - Volume #4, Issue #3, Page #07

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

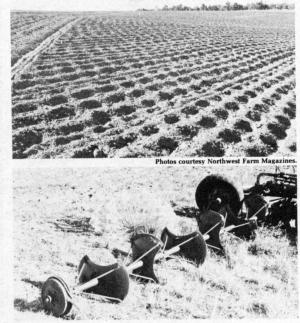

Help Stop Erosion With A Puddler

|

So says Ross Carhart, Dove Creek, Colo. The device he's talking about is a home-made "puddler" which leaves small depressions in the soil to catch and hold moisture.

Carhart made his puddler by spacing old disk blades about 24 in. apart on a shaft and cutting two half-moon notches in each blade. The puddler shaft is 21/2 in. dia. drill pipe, which is about four times heavier than normal steel pipe. The back of each blade is reinforced by four steel braces welded to the shaft and the blade.

As the blades turn, the solid portion scoops out a hole in the soil. The loosened dirt is then dropped as the open section comes around. Alternating the notches and solid portions of the blade (as shown) keeps the puddler running smoothly and evenly spaces "puddles" across the field.

Carhart pulls the puddler behind a one-way disk, but he says it could be used behind a chisel plow, tandem or offset disk, or almost any other tillage tool. His puddler has not been tested in permanent pasture and he doubts if it would be strong enough for use in unworked soil. However, by using heavier blades and axles, and possibly adding some extra weight, it could be used most anywhere, he points out.

In normal operation, the leading end of the puddler is attached by a chain to the rear of the one-way disk. The disk gangs on a one-way operate at approximately a 45? angle to the direction of travel, and the puddler is set to run at about 90? to the one-way disk. The working angle of the puddler determines the size of holes scooped out by each blade. For deeper puddles, the cable from the trailing end of the puddler to the front end of the one-way disk is lengthened. Shortening the cable reduces puddle size.

Carhart says he never uses a disk anymore without the puddler behind it. And, with proper disk spacing and puddler angle, he can even puddle row crops to reduce water runoff.

The puddler requires about 10% as much power as the tillage tool it is working behind says Carhart. Holes are scooped out to about the depth the soil has already been worked.

Carhart says the biggest holes dug by the puddler will hold a five-gallon bucketful of water with no trouble. "We had 81/2 in. of rain during an unusual wet summer spell. Puddled fields had almost no erosion and very little runoff," says Carhart. "The puddles filled up while it was raining, but it had all soaked in before the next rain came. Fields that hadn't been puddled were eroded so badly you could hardly drive through them."

By using old disk blades and other scrap materials, Carhart's puddler cost him only about $50 to build. He says anyone with a little ingenuity and a welder can put one together in a short time.

For more information, contact: FARM SHOW Followup, Ross Carhart, Carhart Feed and Seed, Dove Creek, Col. $1324 (ph 303 677-2233).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.