1980 - Volume #4, Issue #3, Page #08

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

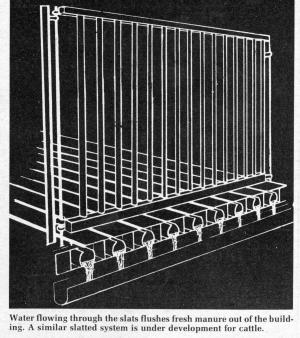

Slatted Floor Has Built-In Sewer

|

"This system eliminates the need for an inside pit, and all the gas, oder and moisture problems that go with it," Don Parks, president, told FARM SHOW.

As shown in the drawing, water flows through the slats, carrying fresh hog manure into an outside lagoon or holding tank and is then recycled through the system.

"You can use it to modernize manure handling and disposal in an existing system, or install it in your brand new confinement facility," explains Parks.

The system requires a slope of 1 in. per 12 ft. of length. "Slightly more slope can be tolerated, but if too much, water will run too fast, causing manure solids to separate out and stay behind," Parks points out. The amount of water flowing through individual slats can be regulated by hand-adjust valves. A 11/z hp. centrifugal pump, costing 6ó per hr. to operate, will circulate the entire amount of water required to flush a 600-hog operation.

Cost of the system, which the manufacturer says is designed for do-ityourself installation, is in the neighborhood of $13 per sq. ft. For growing and finishing hogs, 5-in. wide slats are teamed with 21/z in. dia. pipe. Slats for nurseries (21 in. wide) are equipped 2 in. dia. pipe. All

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.