1990 - Volume #14, Issue #1, Page #26

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

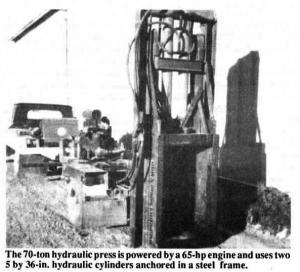

Portable Drum Crusher

|

The 70-ton hydraulic press is powered by a 65-hp engine and uses two 5 by 36-in. hydraulic cylinders anchored in a frame made from square steel tubing. The barrel sits on a metal base and is flattened 3-in. high by a square crusher mounted on the hydraulic cylinders. It'll crush 55-, 30- or 5-gal. drums up to 35 in. tall. Crushing time per drum is 28 seconds.

"My press could crush up to 100 drums per hour, but handling 300 drums is a good day's work," says Jenson, a retired crop sprayer and construction worker. "I started this business two years ago when I had to get rid of 200 55-gal. chemical drums. I couldn't find a landfill that would accept the drums unless they were crushed first. I built the crusher out of scrap iron and powered it with a hydraulic pump and engine from a log splitter. It did the job but worked too slow so I installed the 65-hp V-4 Wisconsin engine."

Jenson charges $3 per drum for crushing the first 100 drums (30 and 55-gal.) and less thereafter. He charges $3 per drum for disposal at the time of crushing in an EPA-approved landfill. He spent about $16,000 to build the drum crusher. He also built a second crusher powered by a 85 hp industrial engine which he uses in Arizona during the winter months.

Contact: FARM SHOW Followup, Don's Drum Crushing, P.O. Box 496, Carrington, N. Dak. 58421 (ph 701 652-2194; in Arizona, 602 684-2582)

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.