1984 - Volume #8, Issue #1, Page #24

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Clothes Line System For Growing Apples

|

He's spent the last 13 years perfecting the revolutionary growing system which is attracting visitors from all corners of the world. A busload from China had been there several days before FARM SHOW arrived to interview Evans. He has about 100 acres "wired up" for apples and estimates that other growers throughout New Zealand using his system account for another 900 acres.

Most of the interest from outsiders has come in only the past several years as skeptics, who maintained at the start that the system wouldn't work, are changing their tune as they watch Evans produce about twice as many apples per acre as they're getting from conventional orchards.

Here's an oversimplification of how the system works:

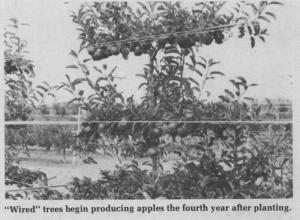

First, you build yourself a special kind of wire "clothes line" for each row of trees. There are four tiers of wires, about 2 ft. apart, with six wires (three on each side of the tree line) per tier. Stretch the wires tight, anchor them securely at each end, and plant the seedling trees. You then prune and train the tree branches to grow along the horizontal wires. Upright growth from the main lateral branches is woven through the outer wires, forming a horizontal fruiting plane.

Here, according to Evans, are the key advantages of his Ebro-Espalier (French for growing crops on a wire) Growing System:

Yield: Trees begin producing earlier, starting with the fourth year. Production is about double that of regular apple trees in a conventional orchard.

Quality: The horizontal planes provide more even light distribution, with no densely shaded areas such as you get with regular trees. This produces fruit of more uniform size and maturity.

Spraying: Due to the system's low shape and profile, savings up to 75% on spraying costs can be achieved. Closeness of the rows, and the low profile, enables spraying to be carried out in windy conditions.

Wind Damage: The wires provide protective support for the branches through all stages of growth, making them less vulnerable to damage from wind, snow or sleet.

Picking: The first three tiers can be picked from the ground, and the top tier from a step stool or simple mobile platform ù no expensive hydraulic ladders are needed.

Pruning: In 15 minutes, a new worker can be trained to do the necessary pruning and working of the branches.

Reworking Trees: As improved varieties are introduced, they can be easily grafted on by removing the laterals, leaving only the stubs on the main leader at each tier of wires.

"I was so impressed with the system after seeing it that I signed up to help promote and market it here in the states," says Jack Henderson, a California based distributor of electric fencing and other products manufactured in New Zealand.

Henderson has a licensing agreement with Evans to market the system, which Evans says is patented in the U.S. in both design and wire configuration. Growers who purchase the system get "how to" construction recommendations and consultation services from Evans.

For more information, contact: FARM SHOW Followup, Ebro-Espalier Growing System, c/o Live Wire Products, Jack Henderson, Pres., P.O. Box 53, Rough and Ready, Cal. 95975 (ph 916 432-1220).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.