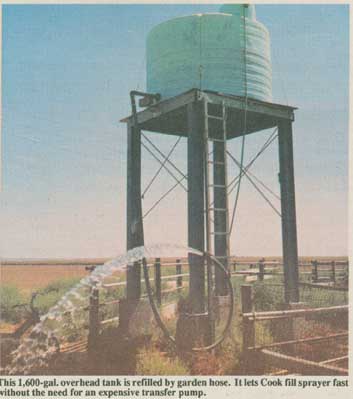

A Kansas farmer has come up with a fast, inexpensive way to fill his crop sprayer and nurse tanks. He built his own 14-ft. high water tower.

Jay Cook, who farms near Dighton, says his water tower cost little to build and is more dependable than a transfer pump because it doesn't require any power source.

"I came up with the idea because I didn't want to spend the money for a transfer pump that I would only use once a year," says Cook. "My water tower is trouble-free and it takes only 15 to 20 min. to completely drain the tower's 1,600-gal. poly tank. I couldn't have justified the cost of a transfer pump with that much capacity. I use a 1 1/2 hp electric pump and garden hose to pump water from my well into the tank. The pump's 7 gal. per min. output closely matches that of my sprayer. I mounted a timer for the pump on a nearby utility pole. I can set it to fill the tank in anywhere from three to six hours. When I leave for the field I know that the tank will be full when I get back.

"My water tower is also a benefit to the community because water is often in short supply here. Neighbors occasionally use the tower to fill their spray tanks. The well is 600 ft. deep so it never goes dry."

Cook got four 12-ft. steel I-beams 10 in. wide from a salvage yard and used them to form the tower's legs. He bolted each I-beam to a concrete pier that's set over a 12-in. deep concrete footing. He made the platform on top of the I-beams out of heavy angle iron, steel pipe, and thick sheet metal. A short steel pipe that comes out of the bottom of the tank is hooked up to a 2-in. dia. plastic discharge hose. A long plastic overflow pipe at the top of the tank prevents water from falling onto the sprayer fill-up area if the tank overfills.

A pair of cables, lined with plastic to prevent corrosion, cross over the top of the tank and secure it to each corner of the platform. "The tank has withstood 80 mph winds without any problems," notes Cook.