1991 - Volume #15, Issue #6, Page #03

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Conversion Kit For Bottom Unload Silos

|

|

"We can convert an oxygen-limiting stave silo to top-unloading for less than the cost of replacing a bottom unloader," says Lyle Knutson of Hanson Silo Co., Lake Lillian, Minn. "Converting stave silos requires more engineering than converting a Harvestore because of concerns about structural integrity. Now that we've started making conversions, we've had a tremendous amount of interest from farmers who've had trouble with oxygen-limiting structures or simply want to get away from the expense of bottom unloaders."

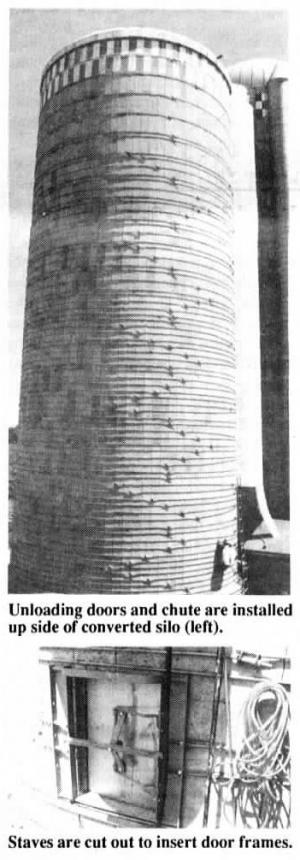

As they do when converting Harvestores, a Hanson crew installs unloading doors and a chute up the side of the silo. They use a regular Hanson silo setup with 45-in. spacing between doors, simply cutting out staves to insert door frames. The trickiest part of the job is loosening the hoops and then repositioning them around the new doors so that the silo doesn't lose any of its support.

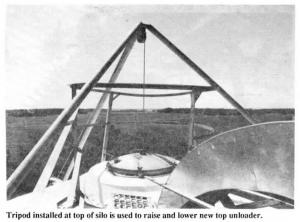

Hanson recently converted a Madison silo, installing an electric winch and tripod on top of the silo to raise and lower the new top unloader. "The farmer was ecstatic with the conversion because he was able to do away with the troublesome bottom unloader. His only other option had been to tear the silo down. There's no sign of weakening at all on the converted silo. Works just like the conventional top-unload silo standing next to it," says Knutson.

For more information, contact: FARM SHOW Followup, Hanson Silo Co., 11587 County Rd. 8 SE, Lake Lillian, Minn. 56253 (ph 612 664-4171).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.