Inexpensive Shaft Monitor

✖  |

"I made a grain drill shaft monitor using off-the-shelf components for less than $100 that eliminates problems with skips," says Ross McGehee, Natchez, Miss., who says his home-built monitor would work on any rotating shaft and many other "out of sight" components such as round baler tailgates.

"My 3-section 28-ft. Crustbuster folding drill tends to throw off drive chains. My monitor lets me know if any of the three feed shafts under the seed boxes stop turning.

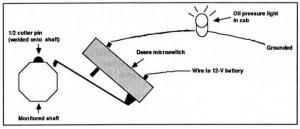

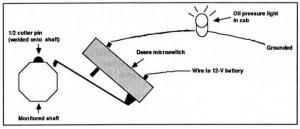

"I welded half a cotter pin to each shaft and then installed a microswitch alongside. The microswitches are standard off-the-shelf units from Deere that are normally used on Deere's combine straw walker monitor. As the shaft turns, it triggers the microswitch each time the switch passes over the cotter pin. The switch is wired to a bank of three lights on a panel in the cab - one light for each switch. The lights are simply oil pressure `idiot' lights. Every time the shaft makes a revolution, it closes the circuit, blinking the light. If the light stops blinking, I know I've got a problem. Works day or night and is foolproof."

Contact: FARM SHOW Followup, Ross McGehee, 404 S. Union, Natchez, Miss. 39120 (ph 601442-6881).

Click here to download page story appeared in.

Click here to read entire issue

Inexpensive Shaft Monitor PLANTERS Planters 15-6-6 "I made a grain drill shaft monitor using off-the-shelf components for less than $100 that eliminates problems with skips," says Ross McGehee, Natchez, Miss., who says his home-built monitor would work on any rotating shaft and many other "out of sight" components such as round baler tailgates.

"My 3-section 28-ft. Crustbuster folding drill tends to throw off drive chains. My monitor lets me know if any of the three feed shafts under the seed boxes stop turning.

"I welded half a cotter pin to each shaft and then installed a microswitch alongside. The microswitches are standard off-the-shelf units from Deere that are normally used on Deere's combine straw walker monitor. As the shaft turns, it triggers the microswitch each time the switch passes over the cotter pin. The switch is wired to a bank of three lights on a panel in the cab - one light for each switch. The lights are simply oil pressure `idiot' lights. Every time the shaft makes a revolution, it closes the circuit, blinking the light. If the light stops blinking, I know I've got a problem. Works day or night and is foolproof."

Contact: FARM SHOW Followup, Ross McGehee, 404 S. Union, Natchez, Miss. 39120 (ph 601442-6881).

To read the rest of this story, download this issue below or click

here to register with your account number.