1984 - Volume #8, Issue #1, Page #04

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

You Should Have Your Tires Slashed

|

|

"Siping", as the company's slashing process is called, isn't new but it's only been used in a few regions of the country, particularly the Northwest. Where the machine has been in regular use, siping has become an almost standard option for both car and truck buyers.

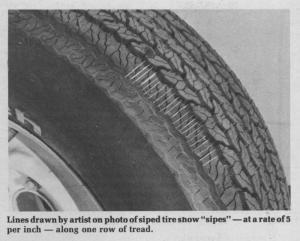

The Saf-Tee Siper machine, marketed by Wes Sprunk, Missoula, Mont., and manufactured by Branick Manufacturing Co., Fargo, N. Dak., makes hundreds of thin slits ù at a rate of 5 per inch ù across the tread on any tire up to 24.5 in. Depending on how much tread is on the tire, the slits run anywhere from 5/32 to 11/32 in. deep.

The advantage of siping tires is that the slits, which run straight across the tread, make the tread more flexible, improving the tire's grip on the road. "You can feel the difference immediately, especially on icy roads," says Sprunk. "Siping gives inflexible tread patterns extra edges to grab with."

The second biggest benefit of siping is wear. The slits allow heat that builds up in tires to disperse, increasing tire mileage by as much as 20%, according to truck fleet operators who have been operating on siped tires for years, and several government testing reports.

"The Navy was having trouble with planes skidding on aircraft carrier flight decks," says Sprunk. "They began siping the tires of jets with our equipment and found the coefficient of friction improved by up to 60%."

Tests by the National Safety Council have shown that siped tires increase breakaway traction (from a standing start) by 64% and reduce stopping distance by 22%. On-the-go traction was improved 28%. Gas mileage is not affected. Sprunk has testimonials from truck fleet operations with hundreds of trucks that testify to the fact that tires wear 20% longer or more with siping. Some tire dealers, including Tom Sherry, Missoula, Mont., told FARM SHOW that a new tire rarely goes out of his store without being siped. Sherry did over $50,000 worth of siping in his tire shop last year with just three machines.

Sprunk says that although officially the major tire companies do not endorse tire siping, they have never turned down a warranty claim on a siped tire. "One large dealer contacted all the major companies and was told that siping would not affect warranties," says Sprunk.

The Saf-Tee siping machine takes up about as much room as a tire balancing machine. It takes just 2 to 3 min. to sipe a tire. A small blade automatically runs back and forth across the tread, making the slits to the desired depth. You can cut to within 1/32 in. of the tread depth of the tire. If there's 6/32 in. of tread, for example, you can cut 5/32 in. deep. The machine will sipe tires from13-in. car tires to 24.5 in. truck tires. The cost is $5 to $10 per tire.

Sprunk says many sports car and motorcycle racing enthusiasts have known the value of siping for years, using sharp knives to sipe tires by hand before competition.

"Besides the increased traction and reduced wear, you get a smoother and quieter ride," adds Sprunk.

The Saf-Tee Siper sells for $3,000 to $4,000, depending on options. Sprunk bought the rights to the machine from its inventor in Mississippi, who sold about 1,000 machines over the last 10 years or so.

If you want to experiment with siping, and you don't want to do all four tires at once, you should do both drive tires. Sprunk says it's possible to sipe tires by hand with a razor blade or sharp knife if you're careful. However, FARM SHOW readers can get as many as four tires siped for free if they bring or ship them to the Branick Manufacturing plant in Fargo, N. Dak., where the tire siping machine is made. You can contact Sprunk for details, or for the name of a tire dealer in your area who sipes tires.

For more information, contact: FARM SHOW Followup, Wes Sprunk, Marcy Manufacturing Co., Ponderosa Center, 2704 Brooks, Box 4247, Missoula, Mont. 59806 (ph toll free 800 526-4061, or 406 728-6750).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.