1980 - Volume #4, Issue #4, Page #04

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Get Ready To Pipeline Your Grain To Market

|

Big pipes carrying grain may criss-cross the country a lot sooner than you might think. In fact, a cornpang in Texas says it could build one right now, make it work, and that it would be competitive in per-bushel transportation cost.

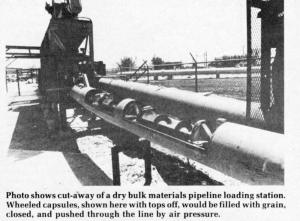

The accompanying photo is a cutaway of an experimental pipeline called "Tubexpress", already available for purchase from Tubexpress Systems, Houston, Tex. Grain would actually move inside capsules that ride along on wheels, pushed by air pressure. No liquid would be involved, and about any size pipeline is possible up to 36 in, in dia., depending on how much grain there is to move.

Actually, twin pipelines side by side would be required - one to move grain to its destination and one to return empty capsules back to the point of origin. The need for twin lines is what keeps grain pipelines from being a great deal less expensive than transportation by conventional systems.

Vaughn Scanland, a vice president at Tubexpress, told FARM SHOW that pipeline size would depend on the tonnage of grain to be moved over a certain amount of time. Capsules would be manufactured to fit pipe size.

His company is looking closely at using its system to move coal as well as grain, "A 30-in. pipeline could move a million tons of coal a year," says Scanland.

The wheeled capsules move along by air pressure, which is only slightly, greater than natural atmospheric pressure, and not by vacuum. Booster air pumps along the line keep the capsules moving, and the pipeline wouldn't have to be completely air tight. Minimum labor to operate would be needed, as the system could be almost fully automated.

Scanland claims that, "Tubexpress is environmentally appropriate. Electric pumps would cause no pollution, and the motorless vehicles traveling underground would cause no noise or visual pollution. The need for highways that gobble up good farmland would be reduced."

Tubexpress' energy requirement would be less per ton-mile than truck haulage, Scanland points out. The system would have a long life, and could be depreciated over 33 years or longer.

As to safety, Scanland says that no derailments can happen, there would be no vehicle collisions, no fire hazard, and no spill hazard.

At Montana State University, Ag Economist Won Koo and others are doing cost evaluation research on running a grain pipeline - perhaps Tubexpress - from Great Falls west to Lewiston, Idaho, where most Montana grain is now shipped. From there, grain is taken by barge via the Columbia River on to the coast at Portland.

"A pipeline capable of handling 80 million bu. of Montana grain a year is economically feasible," says Koo. Construction cost would be $336 million. The cost of moving the 80 million bu., including original cost prorated, would be 53.2 cents per CWT (about 30 cents a bu.). This cost compares with rail operating costs of 58.6 cents/CWT (33 cents/bu.) for single-car rail shipments, or 53.85 cents/CWT (30 cents/bu.) for 50-car grain shipments.

Civil engineering professor Henry Liu, of the University of Missouri, Columbia, who has done alot of research on grain pipelines told FARM SHOW that Canadians successfully moved grain and other bulk cargo through a 300-mile oil pipeline in an experiment a number of years ago.

Liu is trying to develop a grain pipeline system that uses water to move sealed capsules along. Considerable experimentation has been done by others on slurry pipeline systems in which coal, for example, is pulverized and mixed with water to make a "mud" which is pumped along like crude oil. The slurry idea probably wouldn't work for grain, however, Liu points out.

The advantage of the slurry system is that only one pipeline rather than twin lines is required. Liu's capsules would be well sealed and the grain would not get wet, he points out. His proposed system would use electromagnetic pumps to pull the metal capsules along.

Liu cautions that a great deal more work is needed to build an efficient and reliable grain pipeline system. He feels, however, tha

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.