Corn Picker Built From Old Combine

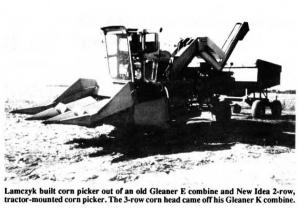

"It gets a lot of strange looks but it works good and saved us a lot of money," say brothers Dave and Barney Lamczyk, DuBois, Ill., about the 3-row self-propelled corn picker they built out of an old Gleaner E combine and a New Idea 2-row, tractor-mounted corn picker.

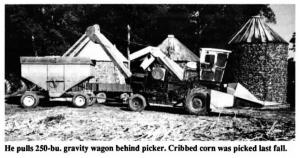

The Lamczyks got the combine free from a friend and bought the picker from another farmer for $500. They stripped the combine down to the frame, keeping the cab, engine, drive train, and wheels and axles. They lowered the engine and remounted the gas tank behind the cab. They used angle iron and steel plate to reinforce the frame and mounted the picker's husking bed over the rear wheels. The picker's two elevators - formerly mounted along each side of the tractor - were bolted onto a "tower" that they welded about halfway back on the frame. The picker's unloading elevator is bolted onto the frame behind the husking bed. The Lamczyks use a 3-row corn head from their Gleaner K combine which they use to harvest shelled corn. They pull a 250-bu. gravity wagon behind the picker.

"It really picks corn fast - about 100 bu. in 30 minutes," says Dave, who notes that they built the picker 1¢ years ago. They used it last fall to pick 2,000 bu. of ear corn that they grind and feed to their cattle. "We spent a total of $1,000. We had been using a New Idea 1-row pull-type picker but it went too slow. Another problem was that we had to run over corn whenever we opened up a field. The 3-row head is as wide as the combine so we can pull into a field and start picking with no waste at all. We use a hydraulic valve to disengage the rear elevator whenever we turn at the end of the field. The husking bed will hold up to 5 bu. We start the elevator up again as soon as the wagon lines up again behind the elevator.

"The 4-cyl., 50 hp engine has plenty of power. The picker is easy to maneuver and back up because the steering wheels are on back. The entire machine is well balanced. There's enough weight on back to keep the picker level even when going downhill with a full wagon.

"Everything is mechanically driven. All three elevators are chain-driven off the combine's main shaft. The husking bed is chain-driven by a right angled gearbox off

the main shaft. A shaft-driven chain delivers corn from the feeder house up to the two elevators. We welded lengths of angle iron onto the chain and mounted rubber paddles on the angle iron to keep ears from shelling.

"It's easy to service. By removing a roller chain and two cotter pins we can slide the husking bed and rear elevator backward off the frame. By removing two bolts and a chain we can remove the rear elevator separately. We mounted extra lights behind the cab so we can see the elevators and husking bed better at night.

"We pull on arope from the cab to control a metal deflector at top of unloading elevator. By changing the position of the deflector we can pitch ears into the front of wagon or we can pitch them to rear of the wagon.

"Each of the two elevators has a stalk deflector on top that separates stalks from ears, dumping stalks onto the ground."

Contact: FARM SHOW Followup, Dave Lamczyk, 1396 W. DuBois Rd., DuBois, Ill. 62831 (ph 618 787-8831).

Click here to download page story appeared in.

Click here to read entire issue

Corn Picker Built From Old Combine COMBINES Conversions 18-2-27 "It gets a lot of strange looks but it works good and saved us a lot of money," say brothers Dave and Barney Lamczyk, DuBois, Ill., about the 3-row self-propelled corn picker they built out of an old Gleaner E combine and a New Idea 2-row, tractor-mounted corn picker.

The Lamczyks got the combine free from a friend and bought the picker from another farmer for $500. They stripped the combine down to the frame, keeping the cab, engine, drive train, and wheels and axles. They lowered the engine and remounted the gas tank behind the cab. They used angle iron and steel plate to reinforce the frame and mounted the picker's husking bed over the rear wheels. The picker's two elevators - formerly mounted along each side of the tractor - were bolted onto a "tower" that they welded about halfway back on the frame. The picker's unloading elevator is bolted onto the frame behind the husking bed. The Lamczyks use a 3-row corn head from their Gleaner K combine which they use to harvest shelled corn. They pull a 250-bu. gravity wagon behind the picker.

"It really picks corn fast - about 100 bu. in 30 minutes," says Dave, who notes that they built the picker 1¢ years ago. They used it last fall to pick 2,000 bu. of ear corn that they grind and feed to their cattle. "We spent a total of $1,000. We had been using a New Idea 1-row pull-type picker but it went too slow. Another problem was that we had to run over corn whenever we opened up a field. The 3-row head is as wide as the combine so we can pull into a field and start picking with no waste at all. We use a hydraulic valve to disengage the rear elevator whenever we turn at the end of the field. The husking bed will hold up to 5 bu. We start the elevator up again as soon as the wagon lines up again behind the elevator.

"The 4-cyl., 50 hp engine has plenty of power. The picker is easy to maneuver and back up because the steering wheels are on back. The entire machine is well balanced. There's enough weight on back to keep the picker level even when going downhill with a full wagon.

"Everything is mechanically driven. All three elevators are chain-driven off the combine's main shaft. The husking bed is chain-driven by a right angled gearbox off

the main shaft. A shaft-driven chain delivers corn from the feeder house up to the two elevators. We welded lengths of angle iron onto the chain and mounted rubber paddles on the angle iron to keep ears from shelling.

"It's easy to service. By removing a roller chain and two cotter pins we can slide the husking bed and rear elevator backward off the frame. By removing two bolts and a chain we can remove the rear elevator separately. We mounted extra lights behind the cab so we can see the elevators and husking bed better at night.

"We pull on arope from the cab to control a metal deflector at top of unloading elevator. By changing the position of the deflector we can pitch ears into the front of wagon or we can pitch them to rear of the wagon.

"Each of the two elevators has a stalk deflector on top that separates stalks from ears, dumping stalks onto the ground."

Contact: FARM SHOW Followup, Dave Lamczyk, 1396 W. DuBois Rd., DuBois, Ill. 62831 (ph 618 787-8831).

To read the rest of this story, download this issue below or click

here to register with your account number.