1991 - Volume #15, Issue #5, Page #36

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Round Bale Compactor

|

|

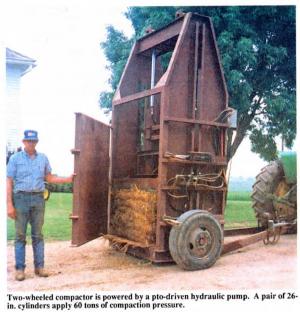

The new two-wheeled compactor is powered by a pto-driven hydraulic pump. A pair of 26-in. hydraulic cylinders apply 60 tons of pressure to a pair of plungers mounted on top of the unit. The plungers are attached to a 2-in. thick steel plate supported by a heavy-duty rectangular steel frame. Rea uses a skid steer loader to load bales into the 54-in. wide, 44-in. deep, and 66-in. high bale chamber, then locks the door shut and flips a lever to activate the plungers. Once the bale has been compacted he manually reties it.

"It reduces bales to almost half their original size and lets me haul almost twice as much hay in my semi trailer," says Rea, who built the compactor 1 1/2 years ago for his custom hay hauling business in Wisconsin and Iowa. "I use it only on high quality bales because they're the most economical to transport. One benefit is that a chain saw can be used to cut the compacted bales into sections that can be rolled onto a two-wheeled cart and fed to cows in the barn. Mother big advantage is that far fewer leaves are lost during handling compared to a full-size bale. The only limitation to my compactor is that bales have to be 48 in. in dia. or less in order to fit inside the chamber."

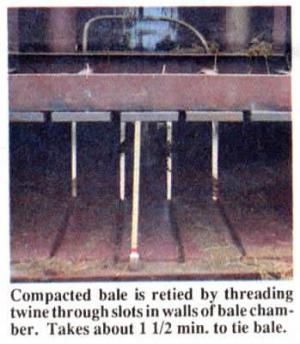

Rea loads the bale into the chamber, then shuts the door and latches it to a pair of 8-in. hydraulic cylinders. Flipping a lever mounted on the side of the compactor causes the cylinders to pull the door shut. Flipping a second lever forces the plungers down. Each side of the frame mounts on a small rubber wheel that rides inside a track to help keep the plungers level when the bale has an uneven density. Rea can compact about 10 bales per hour. "It takes about two minutes to compact the bale and 1 1/2 minutes to tie it. An automatic knotter could be developed to speed up the tieing process. I plan to double my capacity by building another compactor and operating them both at the same time."

The top, front, and bottom sides of the bale chamber have four matching 1 1/2-in. sq. slots that are used to thread twine through to retie bales. Four balls of twine are stored on a shelf in front of the compactor.

A 1/4-in. wide opening between the door and frame allows Rea to see how far the plungers have advanced as they press down on the bale. "The compacted bale is easy to remove because the chamber is 2 in. wider at the opening than at the back of the bale chamber," says Rea, who built the bale compactor for about $10,000.

For more information, contact: FARM SHOW Followup, Dave Rea, 18614 Rt. 151, Bernard, Iowa 52032 (ph 319 879-3412).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.