Manure Handling Without Hangups

✖  |

Just about everything you always wanted in high speed, labor saving manure handling is wrapped up in a revolutionary system introduced by Brooten Fabricating, Brooten, Minn. It's the closest thing we've seen to being able to,l tn.dle manure without the usual hangups, such as having to spend 2 to 6 weeks in the fall with a "honey wagon" when you should be out plow or trying to pump thick, sludgy manure from a pit or lagoon without constant plugging problems.

"We already had what we think is the best traveling gun sprinkler irrigator on the market. We teamed it up with the best manure pump on the market- a go-anywhere unit that we had to go all the way to Austria to find," explains Mitchell Johnson, president of Brooten Fabricating. "It's the only pump we know of in the world that will handle liquid manure as it comes out of a lagoon or pit - and still develop enough pressure to operate a traveling gun sprinkler."

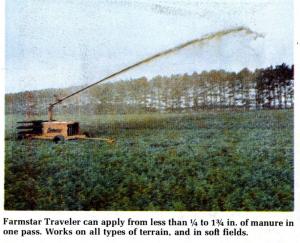

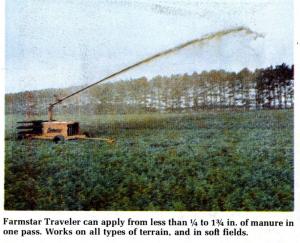

The new Bauer pump, teamed up with the company's Farmstar traveling gun, eliminates the time consuming chore of having to empty pits or lagoons with honey wagons. "With our new system, you can be plowing while the pump and sprinkler work hand in hand to empty the pit or lagoon. When you're done plowing, you're also done handling and pumping manure. Not even wet, rainy weather or soft fields slow up this self-tending manure handling system."

The Austrian-built Bauer helical rotor pumps delivers 235 gpm and up to 150 psi. A 50 hp tractor will handle it. "Nothing plugs conventional pumps faster than plastic artificial insemination gloves, or a slug of afterbirth. This kind of material sails right through this Bauer pump. What's most,just about anything that will go through the pump will also go through the Farmstar sprinkler," explains Johnson.

"While some traveling guns use power from the water stream, the Farmstar open flow-through system utilizes all the pressure and water at the gun for irrigating. This makes it an excellent choice for liquid manure application. Solids can be passed without plugging turbines or orifices," explains Johnson. "The machine is designed to move at a constant speed across the field, regardless of terrain, water pressure, hose drag or cable built up. It features a speed control mechanism called a controlled ratio drive. A roller senses cable build up on the cable drum and automatically changes the ratio of a split sheave, drive-through linkage mechanism. Once ground speed is set, it remains constant. Operating ranges are from 71 to 130 psi, and from 270 to 1,000 gpm.

"Costwise, on,a total system basis, we can compete with honey wagons," Johnson points out. "But we're way ahead when you start figuring in all the labor time spent loading and unloading a honey wagon. Furthermore, our new system can operate in soft, wet fields, and there is virtually no compaction."

Cost of the Bauer pump is $2,975, plus up to $625 extra for optional accessories. Suggested retail cost of the Farmstar traveling gun is $4,850 for the 1/8 m le unit, $12,800 for the 114 mile and $17,046 for the 318 mile unit. The. Bauer pump is readily adaptible fcr use with all three Farmstar traveling guns. If you're handling easy-to-pump liquid manure and don't need the deluxe Bauer pump, lower cost conventional pumps are available.

Brooten Fabricating has launched a new custom lagoon or pit pumping and spreading service. It's available to farmers who don't want to invest in equipment, but still need,to remove manure from a lagoon or pit.

"We go out and size up a farmer's pit or lagoon and the land where he wants the manure spread, then we give him an estimate. We supply the equipment and labor to do the job from start to finish - agitating, laying pipe, pumping and cleanup," explains Johnson. "We already have a lot of interest for spring pumping and spreading, and have begun our spring signup list."

For more details, contact: FARM SHOW Followup, Brooten Fabricating, Box 366, Brooten, Minn. 56316 (ph 612 346-2201).

Click here to download page story appeared in.

Click here to read entire issue

Manure Handling Without Hangups IRRIGATION Irrigation Systems 3-1-17 Just about everything you always wanted in high speed, labor saving manure handling is wrapped up in a revolutionary system introduced by Brooten Fabricating, Brooten, Minn. It's the closest thing we've seen to being able to,l tn.dle manure without the usual hangups, such as having to spend 2 to 6 weeks in the fall with a "honey wagon" when you should be out plow or trying to pump thick, sludgy manure from a pit or lagoon without constant plugging problems.

"We already had what we think is the best traveling gun sprinkler irrigator on the market. We teamed it up with the best manure pump on the market- a go-anywhere unit that we had to go all the way to Austria to find," explains Mitchell Johnson, president of Brooten Fabricating. "It's the only pump we know of in the world that will handle liquid manure as it comes out of a lagoon or pit - and still develop enough pressure to operate a traveling gun sprinkler."

The new Bauer pump, teamed up with the company's Farmstar traveling gun, eliminates the time consuming chore of having to empty pits or lagoons with honey wagons. "With our new system, you can be plowing while the pump and sprinkler work hand in hand to empty the pit or lagoon. When you're done plowing, you're also done handling and pumping manure. Not even wet, rainy weather or soft fields slow up this self-tending manure handling system."

The Austrian-built Bauer helical rotor pumps delivers 235 gpm and up to 150 psi. A 50 hp tractor will handle it. "Nothing plugs conventional pumps faster than plastic artificial insemination gloves, or a slug of afterbirth. This kind of material sails right through this Bauer pump. What's most,just about anything that will go through the pump will also go through the Farmstar sprinkler," explains Johnson.

"While some traveling guns use power from the water stream, the Farmstar open flow-through system utilizes all the pressure and water at the gun for irrigating. This makes it an excellent choice for liquid manure application. Solids can be passed without plugging turbines or orifices," explains Johnson. "The machine is designed to move at a constant speed across the field, regardless of terrain, water pressure, hose drag or cable built up. It features a speed control mechanism called a controlled ratio drive. A roller senses cable build up on the cable drum and automatically changes the ratio of a split sheave, drive-through linkage mechanism. Once ground speed is set, it remains constant. Operating ranges are from 71 to 130 psi, and from 270 to 1,000 gpm.

"Costwise, on,a total system basis, we can compete with honey wagons," Johnson points out. "But we're way ahead when you start figuring in all the labor time spent loading and unloading a honey wagon. Furthermore, our new system can operate in soft, wet fields, and there is virtually no compaction."

Cost of the Bauer pump is $2,975, plus up to $625 extra for optional accessories. Suggested retail cost of the Farmstar traveling gun is $4,850 for the 1/8 m le unit, $12,800 for the 114 mile and $17,046 for the 318 mile unit. The. Bauer pump is readily adaptible fcr use with all three Farmstar traveling guns. If you're handling easy-to-pump liquid manure and don't need the deluxe Bauer pump, lower cost conventional pumps are available.

Brooten Fabricating has launched a new custom lagoon or pit pumping and spreading service. It's available to farmers who don't want to invest in equipment, but still need,to remove manure from a lagoon or pit.

"We go out and size up a farmer's pit or lagoon and the land where he wants the manure spread, then we give him an estimate. We supply the equipment and labor to do the job from start to finish - agitating, laying pipe, pumping and cleanup," explains Johnson. "We already have a lot of interest for spring pumping and spreading, and have begun our spring signup list."

For more details, contact: FARM SHOW Followup, Brooten Fabricating, Box 366, Brooten, Minn. 56316 (ph 612 346-2201).

To read the rest of this story, download this issue below or click

here to register with your account number.