2021 - Volume #45, Issue #3, Page #16

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Rebuilt Antique Sawmill Leads To Solar-Powered Kiln

|

|

“I use the wood cut by the mill to build furniture for local customers,” says Rich. “The mill was probably built in the early 1900s and came with a wooden carriage, which rides back and forth to deliver logs to a 48-in. dia. blade. The mill was sitting in some overgrown brush when I bought it, with a couple of 6-in. dia. trees growing up through the main carriage assembly. The wooden track had rotted away, so we made a new track by merging the frames off a pair of old 1 1/2-ton dually pickups - a 1935 Ford and a 1937 Chevrolet. We also built a new steel carriage.”

He says the sawmill had changed hands and been modified many times over the years. “It originally came with a 30-in. dia. blade and was designed to be powered by a Model A car transmission. The owner replaced the transmission with the flat belt off an older tractor, and later another owner used his tractor pto. We still pto-drive the blade, but we added a hydraulic motor with a directional control valve to move the carriage back and forth. The motor drives a drum with cable hooked up to one end of the carriage. We kept the flat belt pulley on the mill just for looks.”

To anchor the track, they filled cardboard tubes with cement and sank them 4 ft. deep in the ground.

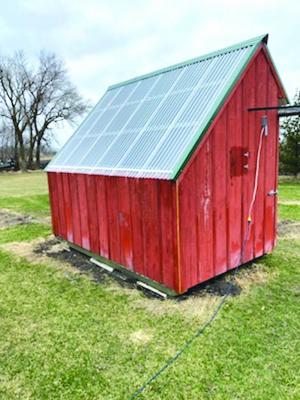

Their solar-powered kiln is also unique. Made mostly from recycled material, it measures 12 ft. long by 7 ft. deep and 12 ft. tall, with big sliding doors on one side. Some 2 by 6’s from an old corn crib were used to build the frame, and the siding is from an old barn. The south-facing roof is pitched at a 45-degree angle and covered with clear polycarbonate sheeting, while the interior is painted black to absorb the sunlight. The walls and floor have 6 in. of insulation. A couple of fans circulate the heated air.

The kiln’s short north-facing roof is made from recycled tin. “There are two intake vents under the eave, and 4 small trap door vents below the sliding doors which allow air to escape,” explains Rich.

They used the kiln for the first time this spring to store pallets loaded with sawmill-cut boards. “It heats up fast. One day the outside temperature was in the mid 50s, but inside it was 114 degrees,” says Rich.

The only new material they bought was plywood for the floor and the polycarbonate sheeting. They used blemished red oak lumber to build a 10-ft. wide pallet for hauling boards into the kiln. “The loaded pallet is heavy and tippy, so we have to drive our skid loader very carefully,” notes Rich.

Contact: FARM SHOW Followup, Rich Vogelsang, 5101 200th Ave., Wells, Minn. 56097 (ph 507 317-2358; sharichv@bevcomm.net).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.