2015 - Volume #39, Issue #5, Page #38

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Corn Crib Reborn As Farm Shop

|

|

|

|

The “something useful” was a 30 by 32-ft. storage shed. One crib was originally slatted for ear corn, while the other had been converted for dried grain storage. Reischauer tore away the crib slats and side and overhead bins, completely gutting the inside of the building. He left the framing studs for the side cribs. The roof was still good, so it was left as is. He covered the exterior with steel siding and installed overhead garage doors at either end of the concrete alleyways.

The two crib floors were concrete. Both were raised about a foot above the alley floor. The ear corn side had a dragway built in, while the shelled corn side was flat.

“I poured concrete in the ends of the dragway, filled it with crushed rock and poured concrete on the top for a flat surface,” says Reischauer. “I left most of the uprights in place on the cribs, but cut out two, 6-ft. wide openings in each for easy access and air movement.”

Some studs had to be replaced, but Reischauer had salvaged useable wood when gutting the interior. “I spent a lot of time pulling nails and ripping 2 by 4’s to replace rotted studs,” he recalls.

Reischauer says the entire project cost him about $3,000, primarily for steel siding and doors. Some salvaged 2 by 12’s were put to use as headers for the entry doors, while 2 by 4’s were doubled up on the exterior for mounting siding.

“There was a lot of rotted wood that had to be removed and burned,” says Reischauer. “However, most of what I did to the building was with salvaged wood. I have a workbench and storage shelves on one side and storage on the other.”

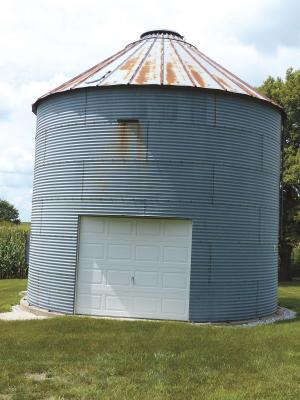

Reischauer also intended to take down a couple of old grain bins on the site. He decided to also repurpose one of them. He removed the drying floors and cut openings in the side for an 8 by 10-ft. garage door.

“To close the gap above the door frame, I took a 2 by 12 and used a jigsaw to cut an arc along one side to fit the curve of the bin,” says Reischauer. “To make the upright jams for the door, I ripped 2 by 6’s at an angle. With the beveled angles set against the sides of the bin, the remainder of the jambs were square with the door.”

Reischauer placed 1-in. weatherstripping between the jams and the bin walls. As the jambs were bolted to the corrugated metal, the insulation filled the gaps for a tight seal.

Garage door tracks are supported with 1/2-in. metal conduit. Reischauer flattened the ends on them and mounted one from the end of each track to the ceiling of the bin for vertical support. A second set of conduits attaches the track ends to the sidewalls for horizontal support.

“The bin works great for storage of lawn mowers and other equipment and materials,” says Reischauer.

Contact: FARM SHOW Followup, Howard Reischauer, 67768 120th St., Zearing, Iowa 50278 (ph 641 487-7673; hljmr@netins.net).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.