Drill-Powered Dehorner Gets Job Done Quick

✖  |

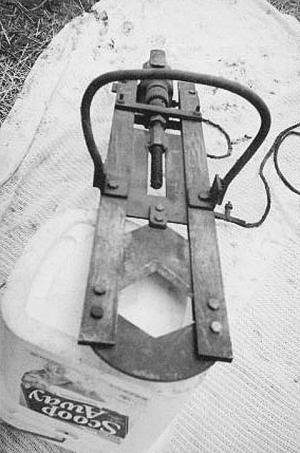

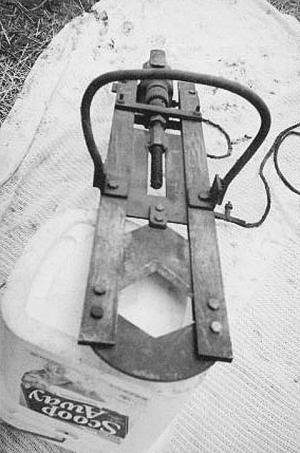

If you've ever dehorned a calf or cow with a hacksaw, you know it's not a lot of fun. The bigger the horn, the worse the job. Jim Pardoe used a long-handled dehorner called a guillotine, but it wasn't that much easier to use. He decided to automate.

"I took the blades from the guillotine and put them in a frame that's powered by a 1/2-in. drill," says Pardoe.

The frame consists of four lengths of 1-in. wide, 1/4-in. steel strap. Two lengths bolted together with spacers between them form each leg of the frame. Cross bars combined with pressure bolts at the end of the frame lock the drill in place. One of the dehorner blades is bolted to one side of the straps at their lower end, with the cutting edge facing the drill. The second cutting edge faces the first, but is mounted to a steel plate. The steel plate has room to slide between the sides of the frame and push the second edge down and over the first blade. A piece of U-shaped steel rod attached to the dehorner frame lets the operator lift the dehorner into place with one hand while the other operates the drill.

"A length of 3/4-in. threaded rod runs through a collar on the plate to the chuck of the high torque, reversible drill," explains Pardoe. "When I trigger the drill, the rod drives the sliding cutting blade down and across the stationary blade. It will cut through anything."

Contact: FARM SHOW Followup, Jim Pardoe, RR 1, Box 1218, Forksville, Penn. 18616 (ph 570 924-3417).

Click here to download page story appeared in.

Click here to read entire issue

Drill-Powered Dehorner Gets Job Done Quick LIVESTOCK Beef 32-3-34 If you've ever dehorned a calf or cow with a hacksaw, you know it's not a lot of fun. The bigger the horn, the worse the job. Jim Pardoe used a long-handled dehorner called a guillotine, but it wasn't that much easier to use. He decided to automate.

"I took the blades from the guillotine and put them in a frame that's powered by a 1/2-in. drill," says Pardoe.

The frame consists of four lengths of 1-in. wide, 1/4-in. steel strap. Two lengths bolted together with spacers between them form each leg of the frame. Cross bars combined with pressure bolts at the end of the frame lock the drill in place. One of the dehorner blades is bolted to one side of the straps at their lower end, with the cutting edge facing the drill. The second cutting edge faces the first, but is mounted to a steel plate. The steel plate has room to slide between the sides of the frame and push the second edge down and over the first blade. A piece of U-shaped steel rod attached to the dehorner frame lets the operator lift the dehorner into place with one hand while the other operates the drill.

"A length of 3/4-in. threaded rod runs through a collar on the plate to the chuck of the high torque, reversible drill," explains Pardoe. "When I trigger the drill, the rod drives the sliding cutting blade down and across the stationary blade. It will cut through anything."

Contact: FARM SHOW Followup, Jim Pardoe, RR 1, Box 1218, Forksville, Penn. 18616 (ph 570 924-3417).

To read the rest of this story, download this issue below or click

here to register with your account number.