1979 - Volume #3, Issue #1, Page #16

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Electrostatic Sprayer Uses 50% Less Chemical

|

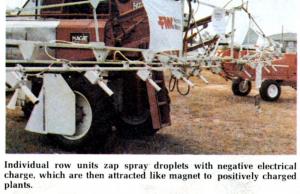

The sprayer mixes air and chemical solutions under pressure in a nozzle, then zaps the mixture with an electrical charge. Each droplet is given negative charge as the spray cloud is atomized. Because they are grounded, plants at which the spray is aimed have a natural positive charge and thus attract the negative droplets.

Air and liquid, held at 20 to 40 psi by a compressor mounted on the sprayer, are pumped into the nozzles through two small tubes. An electronic power unit mounted on each nozzle steps up the low battery voltage to 500-1000 volts. This low amperage high voltage charges each droplet as it's blown through the tiny hole in the end of the nozzle.

That combination of liquid and electricity may sound dangerous, but Dr. Ed Law, who pioneered the electrostatic concept at the University of Georgia, says the charge put out by each nozzle is no stronger than the spark produced by a spark plug. "There is a lot of voltage but there's very little power- only about 1l3 of a watt - so there's no danger," he told FARM SHOW,

Having a power supply on each nozzle means that there are no high voltage cables running across the sprayer. The system runs off any 12-volt system and that's the most voltage any exposed cables carry, the manufacturer explains.

FMC is manufacturing the new electrostatic sprayer under a licensing agreement with The Research Corporation, a non-profit firm in New York which holds the patent. The company has developed a prototype 12-row sprayer which was field tested last year. Company officials plan to test market the sprayer this year and have a model commercially available by 1980, according to Marion Merideth, FMC advertising manager.

The new technology sprayer has been used only for insecticides, and mainly on cotton. Its developers says there is no reason it should not work with herbicides - they just haven't had time to experiment with them. They say that any chemical that will hold an electrical charge can be effectively run through the sprayer. FMC plans to test the sprayer in other crops this year, according to Merideth.

The sprayer requires 50% less chemicals than conventional sprayers because the spray is actually attracted to plants - like metal to a magnet -- and little chemical is wasted. "We've found that with half the material, we've had a good or better results as with conventional sprayers and full applications," says Merideth.

An important part of the sprayer is a control panel mounted near the driver. The panel regulates voltage, air pressure, liquid flow and monitors all aspects of the system, including battery level.

For more information, contact: FARM SHOW Followup, FMC Corporation, 5601 Highland, Jonesboro, Ark. 72401 (ph 501 935-1970).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.