1984 - Volume #8, Issue #2, Page #31

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

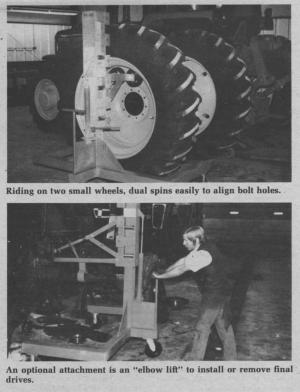

New Shop Jack Makes Changing Duals Easy

|

If the new jack looks familiar to regular FARM SHOW readers, it's because the dual handling mechanism, which consists of two small rubber-coated wheels on a support arm, is virtually the same as a dual changer built by South Dakota farmer Ervin Jensen and featured in FARM SHOW last fall (Vol. 7, No. 5). Jack Niewold, of Shortline Engineering Incorporated, Corwith, Iowa, says he just about had his Duo Jack ready for market when somebody showed him a copy of the story about Jensen's home-built unit.

"I couldn't believe it. It was amazing to me that both of us came up with such a similar idea at the same time. However, our ideas are different in that Jensen's device fits on the front end loader of a Bobcat, whereas the Duo Jack is self-contained."

The dual tire is lifted from the inside of the rim by the steel wheels. Once on the wheels, the dual can be rotated to make finding bolt holes a simple operation. The tractor dual can also be easily transported on the jack's rugged frame and big wheels for storage or remounting.

The main frame of the jack is a tripod configuration that rolls on three 8-in. wheels rated at 1,200 lbs., which gives the unit a 3,600 lb. capacity. The rear wheel swivels and is rigged with a brake for slopedfloors. The mast of the jack is raised and lowered with a 3,000 lb. 18-in. stroke pivoting jack. Because the transport wheels are large, the jack is easy to push around even with a load on, according to Niewold.

The idea for the unique dual jack came to Niewold from a device used for changing truck duals that rolls the dual on wheels on the outside of the tire. That wouldn't work as well with tractor tires because of the lugs, so he came up with the idea of trying it inside.

Besides the attachment for changing tractor duals, the Duo jack has several other unique shop attachments that are attracting farmers and implement dealers. One is an "elbow lift" attachment with a ratchet jack for the removal and/or replacement of final drives with precise horizontal, vertical, and perpendicular plane alignment.

Another attachment is a conventional boom for lifting just about anything. A cable runs off the end of the boom, which is lifted by the hydraulic jack in the mast. There's also a conventional fork attachment, and a V-bar attachment for mounting and dismounting of the heavier convex inner tractor wheels that won't accommodate the dual wheel changer.

The main frame of the jack sells for $959 and the attachments range from $200 to $300. The dual wheel changer attachment sells for $239.

For more information, contact:FARM SHOW Followup, Shortline Engineering Inc., Main Street, P.O. Box 224, Corwith, Iowa 50430 (ph 515 583-2267).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.