1983 - Volume #7, Issue #3, Page #03

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

New Plastic Liners For Upright Silos

|

"We're really pleased with it," reports Canadian dairy farmer Jerry Row, of Curries, Ont. He's used plastic liners in his 14 by 45-ft. concrete silo for the past 3 years. The Sealtite liners he uses are manufactured by Chantler and Chantler, of Mississauga, Ont.

The liners can be used in any upright silo ù wood, concrete, stave or whatever ù that's in good shape and properly hooped for storing high moisture corn. Cost of the liners, made of 6 mil plastic, range from $208.30 for a 16 by 50 silo; $228.50 for a 24 by 50; and $442.55 for a liner to fit a 24 by 100 ft. silo.

Here, courtesy of the Ontario Milk Producers magazine, is how dairy-man Jerry Row uses plastic liners in his 14 by 45 ft. concrete silo to get low cost storage for high-moisture corn:

The liner, which is suspended in-side the silo before filling, is tied after it's full so that it's sealed. The key is to make sure that nothing damages the liner and breaks the seal.

"It is a fragile system and it has to be thought out really carefully to be sure that you don't put any strain on the plastic," Jerry explains.

The Rows covered the silo doors with a roll of tar paper to eliminate any rough surfaces the first year they decided to use the system. Jerry also did some work on the roof.

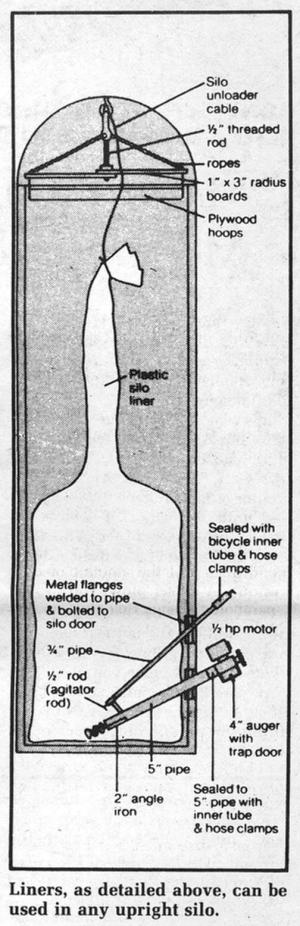

One of the important pieces of equipment in the system is the auger. Jerry's is a small (4 in.) one inside a heavier piece of pipe.

"Flanges are welded to the pipe and those are bolted through the silo floor so that this outside pipe is stationary. The inside pipe, with the auger, can slide in or out," Jerry explains (see drawing).

Another important piece of equipment in the system is what Jerry calls the agitator rod.

"This is a rod that we can use to shake the corn loose over the auger if it bridges," he explains.

It's a 3/4 -in. pipe which has the same type of flange on it as the auger pipe, also bolted through the silo doors. A half inch rod runs through the pipe, and has a handle on each end.

"We can push that rod in or out or turn it to shake the corn loose. We've had to use it some. You need something like that with that small an auger," Jerry says.

It is important to seal both the agitator rod and the auger, and Jerry has done this using a piece of inner tube from a bicycle and some hose clamps.

In spite of all his careful planning, there is one element of the system that Jerry would like to improve. He recommends changing a flat bottom silo.

"Put a barrel in the middle and then cone it up to a 45? angle around the edges. This way, most of the corn will run right out of it," he says.

"The bag is suspended by two plywood hoops which are 4.27 metres (14 ft.) around, the size of the silo. The hoops are strips of 5/16 inch plywood about eight in. wide, and are flat around the silo. The bag is clamped at intervals between the two hoops, which are lowered to the bottom of the silo for this purpose, Jerry explains.

The bag must be well sealed around the auger. Jerry cuts a hole in the bag once he has it near the top of the silo, then slides the bag over the pipe that the auger is in. A seal is made by using plastic and tar paper over the flanges and the silo door. The weight of the corn pushes the bag up against the plastic on the door. This creates a tight seal.

Last year Jerry tried another innovation to try to improve the seal.

"We put a new bag in but this time we left the old bag in. We clamped it back into the hoops along with the new one, and took it up. This gives extra protection against any roughness in the silo. If it's a rough silo, I think the two-bag method is probably worthwhile."

After filling, Jerry unclamps the new bag, removes it from the hoops and ties it off with wire. Although the bag is no longer in the hoops, it is still suspended by the silo unloader cable. From this point forward, maintaining the seal is the key to the success of the plastic silo liner system.

"We have had holes in it every year I think. Last year we only found one little hole. You will findthat the corn starts to get a bit musty coming down. It smells a little off. There is enough slack in the bag that you can go up and walk around on top of the corn and find the hole and patch it with timsmith's tape," explains Jerry.

For more information. Contact: FARM SHOW Followup. Chantler & Chantler 880 lakeshore Road East Box 129 Port Credit, Ont. L5G4L7 Canada (ph. 416-274-2533

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.