Galvanized baling wire with "30% more strength" is new from the Wire Products Division of M.A. Mottos Enterprises, Patterson, Calif.

The new "super strength" wire won't rust, corrode or deteriorate even when exposed to all kinds of weather for a prolonged period of time, according to M.A. Mottos, president. "Ground moisture doesn't affect the galvanized coating. You save both the bottom and top layer of bales when hay is stacked outside."

"The wire is especially good when used with the new high-capacity balers and the new automatic beds that lay bales flat," explains Mottos. "It holds up well under high speed tying and, because of its strength, allows more hay to be packed into each bale."

For 15 years, Mottos was a "balerman" and at one time owned and operated 5 automatic hay balers: "I've used and sold virtually every brand of foreign and domestic baler wire made, and have used both the good and the bad. I know the headaches of broken bales, missed ties, and, worst of all, tangled wire."

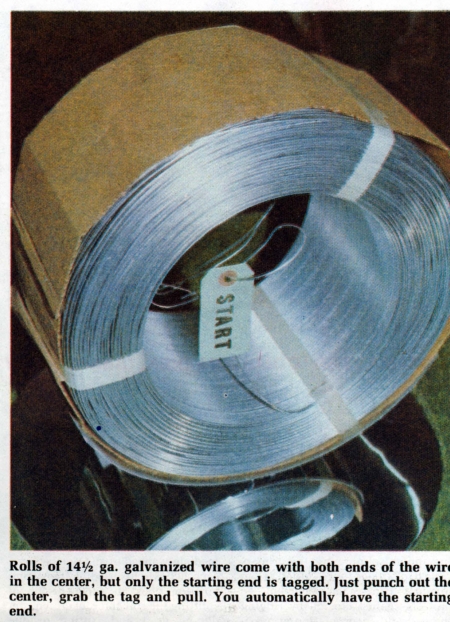

His new galvanized wire comes in a new patented "Zip-Top Easy-Out" box which he designed and patented. It has perforations along the top and sides which allow the operator to simply strike the side of the empty box with his hand to open the box for fast removal without use of a knife or other tool.

It's expected that some custom operators will

run enough bales with galvanized wire for the bottom and top layers, then

switch to black wire for customers who don't want to pay the premium for

"galvanized" on all bales.