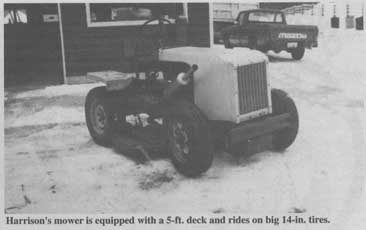

"It works better than any other riding mower I've ever seen and cost very little to build," says Glen Harrison, Sharon, Ont., about the 5-ft. wide riding mower he made from a Mazda pickup.

"It has a lot of power and cuts fast. It's like having an extra large garden tractor," says Harrison, who built the riding mower 2 years ago. "People who see it for the first time always ask what kind of tractor it is. They think I'm joking when I tell them we built it ourselves. I already had the pickup and bought the mower deck. A comparable commercial riding mower equipped with a 5-ft. deck would cost about 10 times as much and would have far less power. It cuts about twice as fast as a conventional riding mower and has a top speed of 25 mph. It's also fuel efficient -- I can cut my 3 1/2-acre lawn twice on 2 1/2 gal. of diesel fuel. It works good on slopes because it's built heavy and low to the ground and rides on big 14-in. tires. I can drive it across a 45 degree slope without even sliding. I cut in first or second gear depending on grass height. I flip a toggle switch on the dash to engage the electric clutch and use a homemade lever to raise or lower the deck. I can quickly remove the deck by taking out four pins and slipping the lift arms off."

Harrison started with a 1984 Mazda B2200 2-WD pickup equipped with a 4-cyl., 70 hp diesel engine and 5-speed transmission. He kept the pickup's engine and transmission, axles, rear end, steering shaft, steering box, spindles, ball joints, tires, and springs. He made a new frame from 4-in. channel iron. To make a new narrowed-up front axle, he cut the spindles off the original axle and welded them onto lengths of 2 1/2-in. dia. steel pipe. A kingpin mounted between both pipes allows the axle to oscillate. The frame narrows toward the front axle, which is 6 in. narrower than the rear axle to shorten up the turning radius.

He removed the pickup's driveshaft and mounted the rear end with the input shaft facing the rear of the tractor. The transmission extends to the back of the tractor so that its output shaft is directly over the rear end's input shaft. Harrison put a small sprocket on the transmission shaft and a big sprocket on the rear end to gear it down.

He bought a used 3-blade, 5-ft. wide deck off a Massey Ferguson riding mower and adapted the mower's lift arms to fit the tractor. The deck is belt-driven off the engine crankshaft by the mower's electric clutch, wliich is mounted on front of the tractor.

Harrison used sheet metal to make the hood which is secured by two bolts and flips forward for easy access to the engine. The radiator screen is off 4 big truck and was cut down to make it fit. He mounted the pickup's air cleaner next to one side of the engine. He bought a new muffler and mounted it on a length of pipe that mounts directly onto the engine exhaust manifold on the other side of the engine. "I couldn't mount the muffler straight up because I couldn't bend the pipe at a sharp angle," says Harrison. "Mounting the muffler and air cleaner next to the engine keeps them from catching on tree limbs."