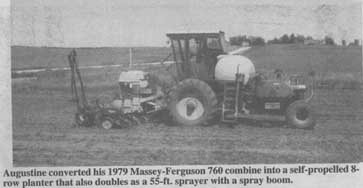

"Nothing can beat it for visibility and maneuverability," says Bill Augustine, Rose Hill, Iowa, who converted his 1979 Massey-Ferguson 760 combine into a self-propelled 8-row planter that also doubles as a 55-ft. sprayer with a spray boom.

Augustine mounted his International 500 semi-mounted, 8-row air planter on front of the combine by cutting away part of the feederhouse to make room for the planter row units. He used steel tubing and sections of steel plate to build quick tach arms to fit the back of the planter. They match quick tach brackets on the feederhouse. He shortened the combine wheelbase 18 in. and moved the cab to the center of the machine after the grain tank and grain threshing components were removed. A 500-gal. spray tank behind the cab carries herbicides. He moved the engine and fuel tank to the back, turning the engine and transmission lengthwise. The combine's original drive tires were too wide for his 30-in. rows so he replaced them with 18.4 by 38 rear tractor tires.

A hydraulic pump that's belt-driven off the engine crankshaft is used to power the planter's blower. The sprayer pump is also belt-driven off the engine crankshaft.

"It gives me a good view of the planter without having to look back all the time," says Augustine, who converted the combine three years ago and has used it to plant about 1,000 acres of corn and soybeans each year. "The combine was in good shape except for the threshing mechanism. I got the idea because I wanted a simple machine that would allow me to both plant and spray, and because I wanted to be able to plant and spray in wet conditions without having to use a tractor. It has good flotation -- I can get in fields where I couldn't go with a tractor. I didn't have to change tire spacing at all. It straddles four rows. I harvest with an 8-row combine so I can follow in the same tracks all year long which limits soil compaction. The planter weighs about the same as a header, so the combine can easily handle the weight. It's easy to steer even in wet conditions.

"I modified the planter for no-till by equipping it with Yetter row units and Martin row cleaners. I mounted a 20-ft. spray boom behind the planter units so that I can apply preemergence herbicides while I plant. Solenoids on the spray boom are wired to a car dimmer switch in the floor-board of the cab so I can use my foot to shut off the boom at the end of the field."

"The combine's 160-hp V-8 Perkins diesel engine has more power than I need. The engine was designed for maximum load at full rpm's and tended to 'lurch' too much. I turned the governor down so it would run smoother at lower rpm's.

"By pulling two pins I can drop the feederhouse and back away from the planter, then quick-mount the spray boom."

Augustine says he thinks any combine with a heavy front axle and transmission and adequate hydraulic capacity would make a good candidate for planting.