There are conventional rotary hoes, and factory-made rotaries designed for minimum tillage. But no manufacturer offers a rotary hoe specifically designed for no-till and heavy "bumper crop" trash.

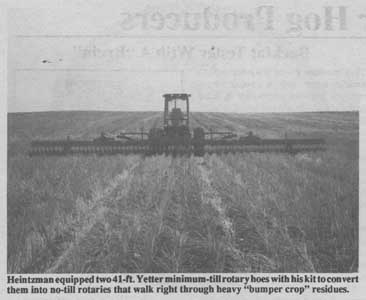

That'll all change as soon as Rick Heintzman, South Dakota farmer and custom operator from Onaka, gets his new no-till rotary hoe conversion kit into commercial production. He's applied for a patent and hopes to have it on the market this fall.

"We've field tested it on more than 3,200 acres. We know it works," says Heintzman of his new invention. Designed to convert major brands of minimum till rotary hoes (including M & W, Yetter and Case-IH, but not Deere) to no-till, it consists of extension arms which reposition the wheels for greater trash and rock clearance, and a new-style wheel mounting axle with a built-in sealed bearing and dust protector. Benefits of the new conversion kit, according to Heintzman, include:

-- Plug-proof performance in heavy trash, thanks primarily to wider spacing between the repositioned wheels.

-- Rock-proof performance, thanks again to the wide wheel spacing which provides constant automatic discharge of rocks and stones, virtually eliminating wheel "lock up".

-- Long life and minimum downtime, thanks to the special Heintzman-designed wheel-mounting axles with sealed bearings and protective dust covers. "We expect to get at least 10,000 acres on a set of sealed bearings and wheels," says Heintzman, who is field testing two 41 ft. Yetter minimum-till rotaries equipped with his no-till conversion kit.

-- Virtually no troublesome wrapping of residue and foreign material -- especially scrap twine and wire -- thanks to repositioning of the wheels to make them self-cleaning. Each rear wheel operates midway between a pair of up-front wheels. Its fingers keep heavy trash moving through without plugging, even under wet conditions.

-- Combining rotary hoeing with conventional, minimum or no-till lets you control weeds in small grain or row crops with little or no dependence on chemical weed killers.

"Timing and weather are the key factors. You've got to be ready to roll when conditions are right -- without downtime, which can be costly.

"I've been rotary hoeing wheat the past four years. For the past two years, I haven't sprayed my wheat at all. I make one pass with my rotary at the 2-leaf stage and then make a second pass a week later. My wheat enters the food chain with no chemicals from planting to harvest and is environmentally safe," says Heintzman.

He anticipates that his conversion kit will be commercially-available this fall. He's also exploring the possibility of incorporating his conversion kit into a complete factory "built from scratch" no-till rotary hoe.