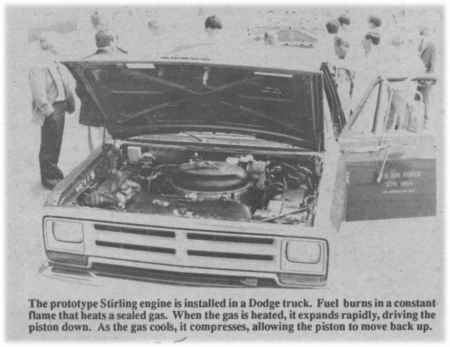

You've never seen anything like the engine under the hood of the Dodge D-150 pickup driven by Albert Richey, Jr., one of the developers of a revolutionary new "external combustion" Stirling engine that gets 30 to 50% better fuel efficiency than similar sized conventional "internal combustion" engines. The Stirling engine burns virtually any kind of fuel including gasoline, diesel fuel, alcohol (methanol or ethanol), LP gas, jet fuel, natural gas, fuel oil, etc. What's more, the engine burns so quietly and efficiently it completely eliminates the need for a muffler, catalytic converter or other emission controls.

The Stirling engine was invented way back in 1816 by British inventor Robert Stirling but until now the materials and technology have never been available to make the unusual engine a commercial success. Now a New York company, Mechanical Technology Inc. (MTI), has developed working prototypes which have received "rave reviews" from government agencies and private companies that have tested the engine, including Deere, which recently tested a van equipped with a Stirling engine.

Unlike conventional internal combustion engines which use spark plugs to explode fuel inside a cylinder to drive a piston up and down, the Stirling engine takes advantage of the fact that high pressure hydrogen gas expands extremely rapidly when heated and compresses quickly when cooled. Cylinders on the Stirling engine are sealed shut with small amounts of high-pressure hydrogen gas inside. When the gas is heated, it expands rapidly, driving the piston down. As the gas cools, it compresses, allowing the piston to move back up again. All that's required is a constant heat source to alternately heat and cool the sealed gas, which is never used up. Virtually any fuel can be used and there's no need for refined fuels with high octane and cetane numbers. The fuel is burned continuously like the flame in a furnace. When more power is required by the vehicle, more fuel is pumped into the fuel chamber and, simultaneously, more hydrogen gas is injected into the sealed cylinders, Richey points out.

He has put more than 800 hrs. on his Stirling-equipped Dodge. The first thing you notice when you look under the hood is the big dome on top of the engine which is the cover of the big combustion chamber. Fuel feeds into it through a single nozzle at the center of the top of the dome. It sprays fuel into the combustion chamber in a 7 degree arc. It burns at temperatures well over 3,000 degrees inside the all-stainless steel chamber. "Heater heads" that extend up into the combustion chamber transfer heat to the gas in the sealed cylinders, driving the engine. The pistons act on a crankshaft just like in a conventional engine and the Stirling will work with any conventional transmission.

The Stirling engine runs quiet because there are no "explosions" of fuel to muffle -- just a constant flame. You never have to change the engine's oil because with external combustion no byproducts, such as carbon, can get into the oil. The starter, alternator and other engine components are the same as on a conventional engine. The only difference in performance is that it takes the engine about a minute to warm up when it's first started.

"We've run this test pickup on unleaded gas, diesel fuel, and even jet fuel without making any adjustments to the engine. You can even mix or match fuels in one tank, using whatever fuels happen to be available, or whichever is least expensive," says Richey.

Deere representative Gregory Guptgsell told FARM SHOW the company was impressed with the new engine. "We got 15 to 30% better mileage with the engine compared to internal combustion engines. And its exhaust emissions were low enough to meet government emission standards for 1990 and beyond." Guptgsell says Deere is evaluating the possibility of manufacturing the engine under license. Another agricultural equipment manufacturer, Valmont Industries, Valley, Neb., is also taking a look at the engine. Valmont is testing a Stirling engine on an irrigation well, fueling the engine with coal. MTI plans to continue tests on the prototype pickup-mounted engine and is considering licensing several companies that want to manufacture it.