Spray Rig Built Out Of Old IH Combine

✖  |

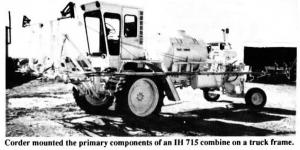

Stripped down old combines can be easily converted into versatile spray rigs that'll outlast any commercial-built machine, according to Tim Corder, Mountain Home, Idaho, who turned an old IH 715 combine into a first class spraying machine with the help of Gilbert Lopez.

"We used all the primary components of the combine including the cab, engine, running gear and hydrostatic drive. We mounted everything on a truck frame we purchased from a salvage yard. The diesel engine delivers its power to the ground through the hydrostatic drive wheels which power the sprayer at speeds from 0 to 18 mph. We used existing control levers in the cab, connecting them by cable to the components of the machine. The drive wheels were enlarged to give greater ground clearance and narrowed for less damage to row crops (14.9 x 38).

"The spray boom mounts on front so the operator can easily see all nozzles from the operator's station. The boom is 50 ft. wide and can be hydraulically adjusted from the cab from ground level up to 5 ft. When raised all the way, the boom lifts over most obstacles and also makes it easy to change nozzles. And because of the parallel linkage on the boom lift, the boom's position in relation to the ground doesn't change as it's lifted and a self-leveling linkage keeps the boom level from side to side. Boom wings can be folded or raised independently using controls in the cab.

"The spray pump is a diaphram type that's driven by a hydraulic motor which is speed-controlled from within the cab. We put electric solenoid controls on each of the three sections of the boom so we can spray in narrow strips when necessary. A Dickey John spray monitor controls the flow and allows us to vary our ground speed, depending on conditions. We also outfitted the spray rig with a foam marker system which eliminates the need to count rows at the turns.

"The spray tank, which mounts on the rear part of the frame, holds 500 gal. but we plan to switch it to 750 gal. this winter.

"We've only used the sprayer one season but we're very pleased with the performance and reliability. We get far more acres sprayed in a day and it's always ready to go. No need to unhook a tractor from another piece of equipment if you just want to spray for an hour or two. It lets us be more timely with all of our spraying because of the speed, ease, availability and versatility of this rig. We looked at the commercial sprayers on the market but they're expensive, smaller, and not as handy or durable. With the exception of the hydrostatic drive wheels, all components are common off-the-shelf parts.

"It's also fun and comfortable to operate. It has an air conditioner, heater, radio and two-way radio. Best of all, we built a valuable piece of equipment using junked parts from a broken down machine."

Contact: FARM SHOW Followup, Tim Corder, T & LC Farms, 303 Aguirre, Mountain Home, Idaho 83647 (ph 208 587-8562).

Click here to download page story appeared in.

Click here to read entire issue

Spray rig built out of old IH combine COMBINES Conversions 13-6-29 Stripped down old combines can be easily converted into versatile spray rigs that'll outlast any commercial-built machine, according to Tim Corder, Mountain Home, Idaho, who turned an old IH 715 combine into a first class spraying machine with the help of Gilbert Lopez.

"We used all the primary components of the combine including the cab, engine, running gear and hydrostatic drive. We mounted everything on a truck frame we purchased from a salvage yard. The diesel engine delivers its power to the ground through the hydrostatic drive wheels which power the sprayer at speeds from 0 to 18 mph. We used existing control levers in the cab, connecting them by cable to the components of the machine. The drive wheels were enlarged to give greater ground clearance and narrowed for less damage to row crops (14.9 x 38).

"The spray boom mounts on front so the operator can easily see all nozzles from the operator's station. The boom is 50 ft. wide and can be hydraulically adjusted from the cab from ground level up to 5 ft. When raised all the way, the boom lifts over most obstacles and also makes it easy to change nozzles. And because of the parallel linkage on the boom lift, the boom's position in relation to the ground doesn't change as it's lifted and a self-leveling linkage keeps the boom level from side to side. Boom wings can be folded or raised independently using controls in the cab.

"The spray pump is a diaphram type that's driven by a hydraulic motor which is speed-controlled from within the cab. We put electric solenoid controls on each of the three sections of the boom so we can spray in narrow strips when necessary. A Dickey John spray monitor controls the flow and allows us to vary our ground speed, depending on conditions. We also outfitted the spray rig with a foam marker system which eliminates the need to count rows at the turns.

"The spray tank, which mounts on the rear part of the frame, holds 500 gal. but we plan to switch it to 750 gal. this winter.

"We've only used the sprayer one season but we're very pleased with the performance and reliability. We get far more acres sprayed in a day and it's always ready to go. No need to unhook a tractor from another piece of equipment if you just want to spray for an hour or two. It lets us be more timely with all of our spraying because of the speed, ease, availability and versatility of this rig. We looked at the commercial sprayers on the market but they're expensive, smaller, and not as handy or durable. With the exception of the hydrostatic drive wheels, all components are common off-the-shelf parts.

"It's also fun and comfortable to operate. It has an air conditioner, heater, radio and two-way radio. Best of all, we built a valuable piece of equipment using junked parts from a broken down machine."

Contact: FARM SHOW Followup, Tim Corder, T & LC Farms, 303 Aguirre, Mountain Home, Idaho 83647 (ph 208 587-8562).

To read the rest of this story, download this issue below or click

here to register with your account number.