No Rust 400 BU Grain Dump Pit

✖  |

"My 400 bu. grain dump pit consists of a steel tank enclosed in concrete. It never touches soil or water directly so it'll never rust," says Duane Riddle, Rochester, Ind., whose high-capacity grain dump pit empties in just 4 to 5 min.

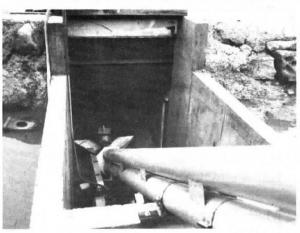

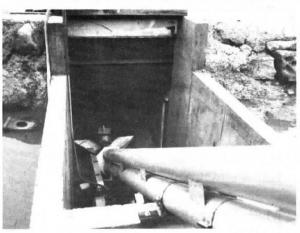

The concrete "jacket" enclosing the painted steel tank is 8 ft. long, 10 ft. wide and 10 ft. deep. The bottom of the bin is positioned above a concrete floor which is 15 in. above a 6-in. layer of pea gravel. The tank is emptied out by a 10-in. dia. horizontal auger that dumps grain into a hopper at the bottom of a 92-ft. long, 8-in. dia. Hutchinson "grain pump". The grain pump runs at a 35? angle to the top of a 36-ft. dia. bin. An inclined gravel driveway leads to the pit's drive-over dump grate. 'Tile surrounds the concrete enclosure to drain excess water to a nearby field.

"I wanted something better than simply installing an old gravity box wagon in the ground or some other kind of steel pit covered by a cement cap and backfilled with sand," says Riddle. "Putting steel in the ground, even painted steel, is asking for trouble because it'll get scratched and corrode.

"I used my dump pit for the first time last fall and it was the first harvest I've had that wasn't a hassle. I had been using a 400-bu. -straight truck and an above-ground 10-in. dia. auger, but it took too long to unload. I farm 1,300 acres by myself on 14 different farms so I don't have much time to waste. When I built this pit I sold my old truck and bought a 1,000 bu. hopper bottom semi-trailer which I use along with a 500-bu. grain cart. It takes less than 10 min. to dump the semi-trailer because the grain pump that empties the dump pit is rated at 4,000 bu. per hour. I can keep my 6-row combine busy with just the one truck and grain cart. And the dump pit slopes at a 45? angle so even 35% moisture corn won't hang up."

Riddle used a backhoe to dig the dump pit hole and hired a contractor to pour the 8-in. thick concrete walls, then had the steel tank custom-built to fit. He made a frame to support the steel tank out of 8-in. wide channel iron anchored in concrete footings and in the concrete walls. Lengths of angle iron welded to the sides of the steel tank rest on top of the beams. Five I-beams set into the top of the concrete walls support the drive-over grate which is made up of 112 by 2-in. bar stock.

"We couldn't set the dump pit more than 7 ft. below ground or water wouldn't have drained by gravity into our field tile drainage system," says Riddle. "So we had to build the top 3 ft. of the pit above ground and build a driveway up to the pit."

The 8-in. dia. Hutchinson grain pump, powered by a 15 hp electric motor, is housed in a concrete enclosure alongside the dump pit. "The grain pump cost al-most twice as much as a 10-in. dia. auger, but it has more capacity, requires less than half as much power, and reduces grain damage," says Riddle. "The 10-in. dia. pit auger is powered by a 5 hp electric motor. It runs at almost 100% efficiency because it's flat and is always loaded down with grain. In fact, I had to install a gearbox to slow it down. If I could do it over I'd install an 8-in. dia. pit auger and build a 500 bu. pit for more capacity. I plan to install an automatic switch which will let me empty the truck and leave immediately. The pit auger will shut off automatically, then after a 15-second delay the grain pump will shut off."

Riddle says the pit cost $5,000 to build which included $2,300 for the concrete enclosure and $1,000 for the drive-over grate. The I-beams were salvaged from an old building.

Contact: FARM SHOW Followup, Duane Riddle, Rt. 3, P.O. Box 161, Rochester, Ind. 46975 (ph 219 223-4830).

Click here to download page story appeared in.

Click here to read entire issue

No Rust 400 BU Grain Dump Pit CROP STORAGE Grain Storage 14-3-11 "My 400 bu. grain dump pit consists of a steel tank enclosed in concrete. It never touches soil or water directly so it'll never rust," says Duane Riddle, Rochester, Ind., whose high-capacity grain dump pit empties in just 4 to 5 min.

The concrete "jacket" enclosing the painted steel tank is 8 ft. long, 10 ft. wide and 10 ft. deep. The bottom of the bin is positioned above a concrete floor which is 15 in. above a 6-in. layer of pea gravel. The tank is emptied out by a 10-in. dia. horizontal auger that dumps grain into a hopper at the bottom of a 92-ft. long, 8-in. dia. Hutchinson "grain pump". The grain pump runs at a 35? angle to the top of a 36-ft. dia. bin. An inclined gravel driveway leads to the pit's drive-over dump grate. 'Tile surrounds the concrete enclosure to drain excess water to a nearby field.

"I wanted something better than simply installing an old gravity box wagon in the ground or some other kind of steel pit covered by a cement cap and backfilled with sand," says Riddle. "Putting steel in the ground, even painted steel, is asking for trouble because it'll get scratched and corrode.

"I used my dump pit for the first time last fall and it was the first harvest I've had that wasn't a hassle. I had been using a 400-bu. -straight truck and an above-ground 10-in. dia. auger, but it took too long to unload. I farm 1,300 acres by myself on 14 different farms so I don't have much time to waste. When I built this pit I sold my old truck and bought a 1,000 bu. hopper bottom semi-trailer which I use along with a 500-bu. grain cart. It takes less than 10 min. to dump the semi-trailer because the grain pump that empties the dump pit is rated at 4,000 bu. per hour. I can keep my 6-row combine busy with just the one truck and grain cart. And the dump pit slopes at a 45? angle so even 35% moisture corn won't hang up."

Riddle used a backhoe to dig the dump pit hole and hired a contractor to pour the 8-in. thick concrete walls, then had the steel tank custom-built to fit. He made a frame to support the steel tank out of 8-in. wide channel iron anchored in concrete footings and in the concrete walls. Lengths of angle iron welded to the sides of the steel tank rest on top of the beams. Five I-beams set into the top of the concrete walls support the drive-over grate which is made up of 112 by 2-in. bar stock.

"We couldn't set the dump pit more than 7 ft. below ground or water wouldn't have drained by gravity into our field tile drainage system," says Riddle. "So we had to build the top 3 ft. of the pit above ground and build a driveway up to the pit."

The 8-in. dia. Hutchinson grain pump, powered by a 15 hp electric motor, is housed in a concrete enclosure alongside the dump pit. "The grain pump cost al-most twice as much as a 10-in. dia. auger, but it has more capacity, requires less than half as much power, and reduces grain damage," says Riddle. "The 10-in. dia. pit auger is powered by a 5 hp electric motor. It runs at almost 100% efficiency because it's flat and is always loaded down with grain. In fact, I had to install a gearbox to slow it down. If I could do it over I'd install an 8-in. dia. pit auger and build a 500 bu. pit for more capacity. I plan to install an automatic switch which will let me empty the truck and leave immediately. The pit auger will shut off automatically, then after a 15-second delay the grain pump will shut off."

Riddle says the pit cost $5,000 to build which included $2,300 for the concrete enclosure and $1,000 for the drive-over grate. The I-beams were salvaged from an old building.

Contact: FARM SHOW Followup, Duane Riddle, Rt. 3,P.O. Box 161,Rochester, Ind. 46975 (ph 219 223-4830).

To read the rest of this story, download this issue below or click

here to register with your account number.