2 In 1 Bale Stabber

✖  |

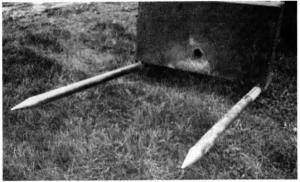

"I put all my round bales into storage 5 to 7 days after baling them so they're usually in good enough shape to move with a single bale stabber. But I needed a forklift during the '88 drought when I was forced to purchase round bales that were rotten on the bottom," says David C. McCoy, Fredericktown, Ohio, who added two extra tines to his home-built "Unicorn" stabber to change it into a convenient "2 in 1" bale handler.

McCoy moves bales with a 50-hp. Deere 2020 utility tractor fitted with a quick-tach Deere 48 loader. He built the bale stabber from a wrecked bucket his neighbor had junked. "I stripped it down to the support frame and the back part of the bucket, and then welded a piece of 1/ 4-in. plate steel to the front of it with a 2 3/4-in. pipe through the center. I welded gussets every 120? on the back to sup-port the pipe. The bale stabber itself is a 4-ft. long, 21/2-in. dia. solid steel pointed rod that's anchored in the pipe holder with a 1/2-in. dia. bolt.

"This bale stabber cost me just $200 to build nine years ago and has hauled thousands of tons of hay with no maintenance or wear. Last summer, to turn it into a forklift mover, I simply added two more pipe mounts on the bottom ends, removed the center bale-stabbing tine, and inserted two tines in the lower mounts. It takes just 5 min. to switch from stabber to forklift. It could easily be fitted with hitch pins to mount on a tractor 3-pt."

When moving heavy bales with the loader, McCoy carries a 55-gal. drum 2/ 3 full of concrete on the rear of the tractor. It's set up to mount quickly on his 3-pt.

Contact: FARM SHOW Followup, David C. McCoy, Rt. 1, 16413 Old Mansfield Rd., Fredericktown, Ohio 43019 (ph 614 397-4664).

Click here to download page story appeared in.

Click here to read entire issue

2 In 1 Bale Stabber HAY & FORAGE HARVESTING Bale Handling (5) 13-1-7 "I put all my round bales into storage 5 to 7 days after baling them so they're usually in good enough shape to move with a single bale stabber. But I needed a forklift during the '88 drought when I was forced to purchase round bales that were rotten on the bottom," says David C. McCoy, Fredericktown, Ohio, who added two extra tines to his home-built "Unicorn" stabber to change it into a convenient "2 in 1" bale handler.

McCoy moves bales with a 50-hp. Deere 2020 utility tractor fitted with a quick-tach Deere 48 loader. He built the bale stabber from a wrecked bucket his neighbor had junked. "I stripped it down to the support frame and the back part of the bucket, and then welded a piece of 1/ 4-in. plate steel to the front of it with a 2 3/4-in. pipe through the center. I welded gussets every 120? on the back to sup-port the pipe. The bale stabber itself is a 4-ft. long, 21/2-in. dia. solid steel pointed rod that's anchored in the pipe holder with a 1/2-in. dia. bolt.

"This bale stabber cost me just $200 to build nine years ago and has hauled thousands of tons of hay with no maintenance or wear. Last summer, to turn it into a forklift mover, I simply added two more pipe mounts on the bottom ends, removed the center bale-stabbing tine, and inserted two tines in the lower mounts. It takes just 5 min. to switch from stabber to forklift. It could easily be fitted with hitch pins to mount on a tractor 3-pt."

When moving heavy bales with the loader, McCoy carries a 55-gal. drum 2/ 3 full of concrete on the rear of the tractor. It's set up to mount quickly on his 3-pt.

Contact: FARM SHOW Followup, David C. McCoy, Rt. 1, 16413 Old Mansfield Rd., Fredericktown, Ohio 43019 (ph 614 397-4664).

To read the rest of this story, download this issue below or click

here to register with your account number.