Trouble Free Thermostat For Livestock Barns

✖  |

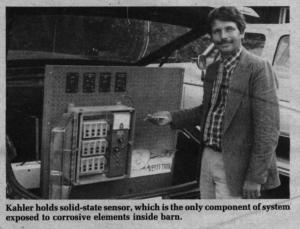

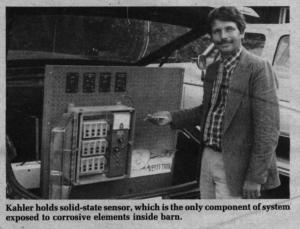

"Many hog producers tell me they have to adjust thermostats daily in confinement buildings due to corrosion, and the fact that electromechanical thermostats often vary in temperature as much as 10? or more," says Wayne Kahler, manufacturer of new solid state temperature controls for any confinement building or greenhouse.

The new thermostats use solid state sensors ù about the shape of a lead pencil and covered with plastic ù that detect temperature changes through a change in resistance of its conductive materials. The sensors are wired to controls that can be mounted in remote locations, such as a service area, so that none of the sensitive electrical parts are exposed to the corrosive environment of the barn.

The temperature control unit turns fans on or off in the building. Sensors are spaced throughout the barn in zones which can be varied to fit the structure. Kahler's state-of-the-art electronics can control variable speed fans and various combinations of fans to create the best possible environment.

The temperature control system, which recently went into production, has been tested in 9 barns over the past couple years. Several of the hog farmers bought the system to retrofit old thermostat controlled barns and others put the system into new barns. Individual thermostats are available to replace thermostats one by one or you can install a complete system. A single Kahler electronic thermostat sells for $99. In general, Kahler says the complete temperature control system sells for about half again as much as conventional electromechanical systems.

Kahler Electric Co. also makes electronic air pressure control systems that provide automatic roof vent control in conjunction with temperature control. Negative Air Pressure Controls, as they're called, maintain proper air pressure automatically regardless of the number of fans operating. When sensors detect a change in air pressure, they send a signal to electric actuators on the building's dampers which then open or close the vents.

"Together with our temperature control system, we can provide the most controlled building environment possible," says Kahler. "One customer told us that he has less sickness and uses less antibiotics because he can keep temperatures within 2 to 3? and can adjust air flow so animals are never in a draft."

For more information, contact: FARM SHOW Followup, Kahler Electric Co., 909 Winnebago Ave., Fairmont, Minn. 56031 (ph 507 235-6301).

Click here to download page story appeared in.

Click here to read entire issue

Trouble free thermostat for livestock barns BUILDINGS Accessories 9-6-28 "Many hog producers tell me they have to adjust thermostats daily in confinement buildings due to corrosion, and the fact that electromechanical thermostats often vary in temperature as much as 10? or more," says Wayne Kahler, manufacturer of new solid state temperature controls for any confinement building or greenhouse.

The new thermostats use solid state sensors ù about the shape of a lead pencil and covered with plastic ù that detect temperature changes through a change in resistance of its conductive materials. The sensors are wired to controls that can be mounted in remote locations, such as a service area, so that none of the sensitive electrical parts are exposed to the corrosive environment of the barn.

The temperature control unit turns fans on or off in the building. Sensors are spaced throughout the barn in zones which can be varied to fit the structure. Kahler's state-of-the-art electronics can control variable speed fans and various combinations of fans to create the best possible environment.

The temperature control system, which recently went into production, has been tested in 9 barns over the past couple years. Several of the hog farmers bought the system to retrofit old thermostat controlled barns and others put the system into new barns. Individual thermostats are available to replace thermostats one by one or you can install a complete system. A single Kahler electronic thermostat sells for $99. In general, Kahler says the complete temperature control system sells for about half again as much as conventional electromechanical systems.

Kahler Electric Co. also makes electronic air pressure control systems that provide automatic roof vent control in conjunction with temperature control. Negative Air Pressure Controls, as they're called, maintain proper air pressure automatically regardless of the number of fans operating. When sensors detect a change in air pressure, they send a signal to electric actuators on the building's dampers which then open or close the vents.

"Together with our temperature control system, we can provide the most controlled building environment possible," says Kahler. "One customer told us that he has less sickness and uses less antibiotics because he can keep temperatures within 2 to 3? and can adjust air flow so animals are never in a draft."

For more information, contact: FARM SHOW Followup, Kahler Electric Co., 909 Winnebago Ave., Fairmont, Minn. 56031 (ph 507 235-6301).

To read the rest of this story, download this issue below or click

here to register with your account number.