1993 - Volume #17, Issue #2, Page #17

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

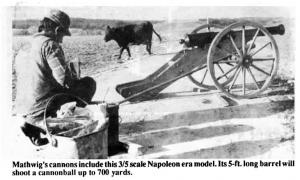

He Builds Cannons Of All Sizes, Types

|

Mathwig's cannons are patterned after 18th and 19th century artillery models and include a 3/5 scale Napoleon era cannon, a 1/2 scale 1849 Civil War cannon, and a miniature 1/6 scale cannon. The Napoleon era cannon has a 5-ft. long barrel that'll shoot a 2-lb. cannonball up to 700 yards. The miniature 1/6 scale cannon has a 1-ft. long barrel that'll shoot small cannon balls right through a 50-gal. steel barrel from 45 yards away.

"I've been interested in cannons ever since I was a kid, but I didn't start building them until 20 years ago after my mother gave me an illustrated book on cannons as a Christmas gift," says Mathwig. "I picked out the kind of cannon I wanted to build and took measurements off the sketches. I make everything from scratch including the wooden wheels and carriage.

"The Napoleon era cannon was originally designedto shoot a 12-lb. cannonball. However, I use a tin can filled with 2 lbs. of concrete and can hit within 3 ft. of the target consistently.

"The barrel has a 53-in. long, 2 7/8-in. dia. bore and weighs about 350 lbs. It really has power. I've shot off 6-in. dia. trees from 200 yards away. Under the right conditions, neighbors can hear it 3 miles away."

Mathwig welded seven pieces of pipe of different diameters together to form the bore so that it would be strong enough to keep from blowing up even if it was accidentally overloaded with powder. He used oak wood for the carriage, 3-ft. high wheels, and spokes. Each wheel rim was formed by boiling two strips of wood and fitting them into a jig, then drying them. A steel band was then drawn around the rim. He used thread protectors from well casings to make the wheel hubs and mounted the spokes inside pockets. The axle was made from a steel shaft covered with wood. An elevating screw is mounted under the back end of the breech and is used to raise or lower the barrel when aiming it.

Mathwig built his 1/2 scale 1849 U.S. land artillery cannon from blueprints obtained from the National Archives. "It was one of the most popular cannons used during the Civil War," says Mathwig. "It had a bronze barrel that weighed 880 lbs. and had a 3.67 in. dia. bore designed to shoot 6-lb. cannon balls. During battle conditions, they used 11/2 lbs. of powder to fire each cannon ball to provide maximum smashing effect.

"A well-trained crew of six men could get off as many as five or six rounds per minute. A long-handled powder ladel was used to deposit powder in the breech. One man loaded the powder, another packed it with a ramrod, another loaded the cannon ball, another aimed the cannon, one commanded the crew and the last man fired the cannon by touching a paper wick soaked in salt peter with a torch. It would fire instantly. The torch was long enough that he would be clear of the recoiling cannon, but close enough that it was awfully hard on the ears. Between shots they swabbed the barrel out with water to extinguish any sparks."

"I use 4 oz. of powder each time I fire the big cannons so I can get only 4 shots out of a pound of powder. Powder is getting more expensive. A few years ago it sold for $1 per lb., but now it sells for about $12 per lb."

To make ammunition for the small can-non he wraps powder in aluminum foil and pinches it shut, then uses a small wooden ramrod to lightly tamp the powder into the breech. He inserts a length of wire through the touch hole and punches a hole into the foil and inserts a fuse. He then rams the powder tight, puts in the cannon ball, and lights the fuse.

"I use a commercial .69 calibre mold to make the small cannonballs. I use `white metal' instead of lead because it doesn't leave a buildup of lead in the bore," says Mathwig. "People are surprised how loud the noise is when it's fired. I use about the same amount of powder that's in a 12-ga. shotgun shell, but the short barrel causes it to make a terrific bang. It a

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.