1985 - Volume #9, Issue #2, Page #21

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

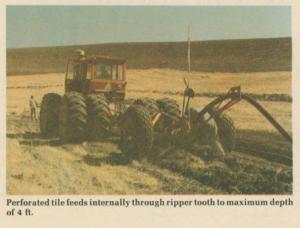

Drain Your Own Felds With Tractor Tiler

|

|

The men used the tiler for the first time last year to lay about 5 miles of tile. Most of it was laid on a 160 acre farm they recently bought but they also did some custom work.

The Fleeners built the tiler from junk components that cost less than $500. They say they can now use "spare time" to lay tile for little more than the cost of fuel and about 25 cents per foot of tile. "Custom operators charge 58 cents per foot and you have to fit into their schedule," says Chris.

A 275 hp. Versatile 850 tractor is enough to pull the tiler through most soils. In heavy clay, the Fleeners hook a crawler tractor up to the front of the Versatile.

"It has a ripper-tooth that feeds 4-in. perforated tile internally within the rear of the tooth. Depth is controlled by its 7-in. dia. hydraulic lift cylinder. Maximum depth is 4 ft.," says Chris.

When the tiler tooth raises above a 4-ft. depth, a hydraulic "heel" lowers at the rear of the tooth to maintain a flat surface along its bottom and tokeep laying tile evenly at the bottom of the trench. "This eliminates the parallel linkages used on other tilers to keep the tile-laying tooth level in the ground. The direct pull of our tiler makes it stronger and less likely to bend or break under heavy stress," says Chris.

The tiler is equipped with a surveyor's rod for use with a transit-level to maintain grade in hilly areas. On level ground, the operator simply watches a measured rod fitted to the tiler that shows tooth depth at a glance.

A backhoe is required to start each line or to splice into existing main lines. The tile is laid out along the surface before being ripped in.

"On a good day, a 3-man crew can lay 5,000 to 6,000 ft. depending on length of lines and amount of backhoe work," says Chris, noting that the tiler was designed mainly for drain tile but will also lay water and sewer line or even power cable.

The main frame of the tiler came from an old deep V-plow. The wheels and other frame parts came from a junked Case hillside combine. Frank built the ripper tooth from scratch.

For more information, contact: FARM SHOW Followup, Fleener Enterprises, Rt. 1, Box 93, Pullman, Wash. 99163 (ph 509 872-2705).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.