1985 - Volume #9, Issue #1, Page #04

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Modification Kit For Goliath Unloaders

|

"It'll boost delivery capacity of your Goliath unloader 50 to 100%, reduce torque and make operation of the unloader much smoother. What's more, the modification isn't expensive and you can install it yourself in less than a half day," Finger told FARM SHOW.

Here's the problem, and how he discovered and solved it:

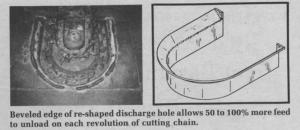

The Problem: Limited discharge capacity, caused by the size and shape of the factory-installed discharge opening. "I made this eye-opening discovery in Feb., 1982 when my 20 by 60 Harvestore Goliath unloader chain hooked a section of floor and pulled it up so the cutter arm couldn't make a complete rotation. The structure was nearly empty but, to get it completely cleaned out, I had to crawl inside and shovel a small pile of haylage into the cutter arm. Once inside, while watching the cutter arm move material to the center discharge hole, I noticed that only about 50% of the loosened material falls into the discharge hole. The rest bypasses to be piled behind the cutter arm, or it rotates on around to put pressure on the cutter chain. Consequently, the cutting chain is constantly trying to dig new feed loose and, at the same time, has to carry around already loosened feed."

The Solution: "I reshaped the center feed discharge hole so it has a beveled rather than a straight edge. The beveled edge works like a funnel, allowing a much greater amount of loosened feed to fall directly into the space between the drag chain paddles and tunnel wall. With this modification, 75 to 100% of the feed cut loose by the cutting chain on each revolution enters and falls through the discharge hole.

"Since making the modification, I only use two V-belts to drive the unloader, instead of four, and get 50 to 100% more discharge capacity, depending on the type of feed being unloaded. Feed comes out in a steady flow, with feed in every conveyor paddle rather than hit and miss as before. The moisture content of haylage isn't as critical as it used to be," Finger points out.

Finger is offering a ready-made kit which includes the necessary hardware, a template for making a replacement feed discharge hopper with beveled edge, and installation instructions.

Cost of the "kit" is approximately $200 for 20-ft. dia. Harvestores, and $225 for 25-ft. dia. structures.

For more information, contact: FARM SHOW Followup, Eddie Finger, Rt. 1, Powhattan, Kan. 60527 (ph 913 474-3424).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.