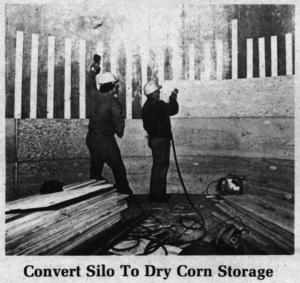

Convert Silo To Dry Corn Storage

✖  |

"We tried plastic, epoxy and cement before hitting on the idea," says Roy Bilyeu, owner of Mason City Silo Repair, Mason City, Iowa, who has developed a process for converting concrete stave silos to dry corn storage. "We've converted more than 100 silos so far and all our customers are satisfied," he told FARM SHOW.

Bilyeu builds a wooden liner completely covering the inside of the silo. The liner insulates dry corn from the moist wall of the silo, creating an air space to evaporate condensation and frost.

"We create a 1-in. air space by nailing 1 x 4's directly to the silo walls, spaced 6-in. apart and running vertically. We then staple 1/4 in. plywood to the 1 by 4's covering the entire inside. In effect, we're building a barrel inside the silo," says Bilyeu.

"We also seal the top of thesilo and pour a concrete floor," he points out. And, if the silo wasn't originally built strong enough to hold corn, we strengthen it with extra hoops."

According to Bilyeu, the key to successful conversion of silos into grain bins is proper aeration of the grain. "We use a 1 1/2 hp. fan blowing through a 6-ft. length of vented 12-in. pipe across the silo floor, blowing or pulling air through the grain."

Base conversion price for a 20-ft. dia. silo is 40 cents per bu. of grain the converted silo holds, plus whatever extra work is needed, depending on condition of the structure and what's needed to ready it for storing shelled corn or other dry grain.

Contact: FARM SHOW Followup, Mason City Silo Repair, 20 9th Street N.E., Box 363, Mason City, Iowa 50401 (ph 515 425-4611).

Click here to download page story appeared in.

Click here to read entire issue

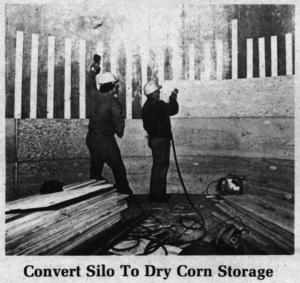

Convert Silo to Dry Corn Storage CROP STORAGE Grain Storage 10-5-28 "We tried plastic, epoxy and cement before hitting on the idea," says Roy Bilyeu, owner of Mason City Silo Repair, Mason City, Iowa, who has developed a process for converting concrete stave silos to dry corn storage. "We've converted more than 100 silos so far and all our customers are satisfied," he told FARM SHOW.

Bilyeu builds a wooden liner completely covering the inside of the silo. The liner insulates dry corn from the moist wall of the silo, creating an air space to evaporate condensation and frost.

"We create a 1-in. air space by nailing 1 x 4's directly to the silo walls, spaced 6-in. apart and running vertically. We then staple ? in. plywood to the 1 by 4's covering the entire inside. In effect, we're building a barrel inside the silo," says Bilyeu.

"We also seal the top of thesilo and pour a concrete floor," he points out. And, if the silo wasn't originally built strong enough to hold corn, we strengthen it with extra hoops."

According to Bilyeu, the key to successful conversion of silos into grain bins is proper aeration of the grain. "We use a 1¢ hp. fan blowing through a 6-ft. length of vented 12-in. pipe across the silo floor, blowing or pulling air through the grain."

Base conversion price for a 20-ft. dia. silo is 40 cents per bu. of grain the converted silo holds, plus whatever extra work is needed, depending on condition of the structure and what's needed to ready it for storing shelled corn or other dry grain.

Contact: FARM SHOW Followup, Mason City Silo Repair, 20 9th Street N.E., Box 363, Mason City, Iowa 50401 (ph 515 425-4611).

To read the rest of this story, download this issue below or click

here to register with your account number.