Farmer Promotes Sod-Till System

After years of experimentation and testing, Ohio farmer David McCoy says he's perfected a first-of-its-kind tillage system that he feels could be the answer for farmers who need to comply with new conservation tillage requirements yet also want to maintain the soil on their farms in as good a shape as it was when their fathers and grandfathers farmed it. He calls his system "Sod Till".

Various pieces of McCoy's equipment have been featured in FARM SHOW over the years. Now he's got patents pending on four main pieces of equipment and he's trying to locate a manufacturer willing to make an investment in an entirely new way of farming.

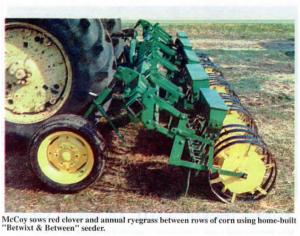

In a nutshell, McCoy's Sod Till system consists of planting a cover crop in between standing row crops (or after harvest, if you live down south and have a longer growing season) and then tilling it under to re-duce fertilizer needs. He sows red clover and annual ryegrass between rows of corn in early July using his home-built "Betwixt & Between" seeder. That creates the "sod" part of Sod Till.

The "till" part consists of three new implements McCoy designed. The first is his Spider Plow, which he uses for primary mulch tillage. It breaks up the sod and crop residue, thoroughly mixes the residue, and then leaves extra residue on the surface. "I ran it side by side in a tillage demonstration with a Deere Mulch Master and farmers watching concluded that it worked as well or better, leaving 63 percent of corn residue on the surface," says McCoy.

The Spider Plow looks somewhat like a tandem disk, with two rows of opposite-facing discs, angled discs front and back, with each gang followed by a row of special-built spider wheels that break up and mix residue.

The second tillage implement is a Spider Harrow which performs secondary mulch tillage and seedbed preparation. It's fitted with three rows of S-tines alternated with rows of angled spider wheels. A chain harrow is dragged behind.

The last piece of tillage equipment is McCoy's Spider Hoe, which he runs through the planted fields once before emergence and once after emergence. It has Lilliston-style spider wheel gangs between the rows and a pair of rotary hoe wheels running on the row. "The Spider Hoe does such a great job cultivating it practically eliminates the need for herbicides," says McCoy, noting that if the weather does not cooperate and weeds get a good jump on him, he removes the rotary hoe wheels on the row and then high-speed cultivates between the rows with just the angled spider wheels.

In addition to his special-built equipment, McCoy also uses row cleaners on his planter to clear residue out of the way. He made his own using Lilliston-type spider wheels.

"My Sod Till system is simple, saves money, and is better for the soil without hurting yields. You save money by growing your own fertilizer since the cover crop, which consists of about 3 lbs. of red clower and 3 lbs. of ryegrass, substantially reduces the need for nitrogen. It also improves organic content of soil, reduces worries about ground water contamination by reducing use of chemicals, and it may be a method that would comply with future regulations. Countries like Sweden

and the Netherlands have already started severely regulating the use of fertilizers and chemicals," says McCoy.

In addition to his field system, McCoy has also developed hand-powered Sod Till equipment for use in gardening, including a hand-pushed "Betwixt & Between" seeder and a hand-pushed Spider Hoe.

For more information, send a self-addressed stamped envelope to: FARM SHOW Followup, David McCoy, Wotokahan Farm, 16413 Old Mansfield Rd., Fredericktown, Ohio 43019 (ph 614 397-4664).

Click here to download page story appeared in.

Click here to read entire issue

Farmer Promotes Sod-Till System PLANTING EQUIPMENT Interseeding 19-3-40 After years of experimentation and testing, Ohio farmer David McCoy says he's perfected a first-of-its-kind tillage system that he feels could be the answer for farmers who need to comply with new conservation tillage requirements yet also want to maintain the soil on their farms in as good a shape as it was when their fathers and grandfathers farmed it. He calls his system "Sod Till".

Various pieces of McCoy's equipment have been featured in FARM SHOW over the years. Now he's got patents pending on four main pieces of equipment and he's trying to locate a manufacturer willing to make an investment in an entirely new way of farming.

In a nutshell, McCoy's Sod Till system consists of planting a cover crop in between standing row crops (or after harvest, if you live down south and have a longer growing season) and then tilling it under to re-duce fertilizer needs. He sows red clover and annual ryegrass between rows of corn in early July using his home-built "Betwixt & Between" seeder. That creates the "sod" part of Sod Till.

The "till" part consists of three new implements McCoy designed. The first is his Spider Plow, which he uses for primary mulch tillage. It breaks up the sod and crop residue, thoroughly mixes the residue, and then leaves extra residue on the surface. "I ran it side by side in a tillage demonstration with a Deere Mulch Master and farmers watching concluded that it worked as well or better, leaving 63 percent of corn residue on the surface," says McCoy.

The Spider Plow looks somewhat like a tandem disk, with two rows of opposite-facing discs, angled discs front and back, with each gang followed by a row of special-built spider wheels that break up and mix residue.

The second tillage implement is a Spider Harrow which performs secondary mulch tillage and seedbed preparation. It's fitted with three rows of S-tines alternated with rows of angled spider wheels. A chain harrow is dragged behind.

The last piece of tillage equipment is McCoy's Spider Hoe, which he runs through the planted fields once before emergence and once after emergence. It has Lilliston-style spider wheel gangs between the rows and a pair of rotary hoe wheels running on the row. "The Spider Hoe does such a great job cultivating it practically eliminates the need for herbicides," says McCoy, noting that if the weather does not cooperate and weeds get a good jump on him, he removes the rotary hoe wheels on the row and then high-speed cultivates between the rows with just the angled spider wheels.

In addition to his special-built equipment, McCoy also uses row cleaners on his planter to clear residue out of the way. He made his own using Lilliston-type spider wheels.

"My Sod Till system is simple, saves money, and is better for the soil without hurting yields. You save money by growing your own fertilizer since the cover crop, which consists of about 3 lbs. of red clower and 3 lbs. of ryegrass, substantially reduces the need for nitrogen. It also improves organic content of soil, reduces worries about ground water contamination by reducing use of chemicals, and it may be a method that would comply with future regulations. Countries like Sweden

and the Netherlands have already started severely regulating the use of fertilizers and chemicals," says McCoy.

In addition to his field system, McCoy has also developed hand-powered Sod Till equipment for use in gardening, including a hand-pushed "Betwixt & Between" seeder and a hand-pushed Spider Hoe.

For more information, send a self-addressed stamped envelope to: FARM SHOW Followup, David McCoy, Wotokahan Farm, 16413 Old Mansfield Rd., Fredericktown, Ohio 43019 (ph 614 397-4664).

To read the rest of this story, download this issue below or click

here to register with your account number.