1985 - Volume #9, Issue #3, Page #25

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

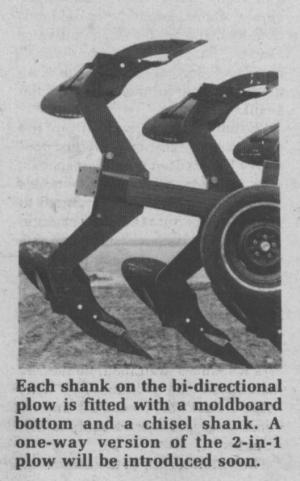

Ripper Plow Does Two Tillage Jobs At Once

|

According to Moore, the Ripper Plow pulls just as easily as any moldboard plow on the market even though it's fitted with a chisel shank that runs anywhere from 4 to 8 in. deeper than the leading edge of the moldboard.

"Farmers who've seen it are excited because it provides the benefits of deep chiseling and yet also turns the soil over. Many farmers who need a chisel to break up hardpan want this plow so they don't have to make an extra trip to turn the soil. Chiseling shatters the subsoil so roots of plants can reach deeper for better growth," says Moore.

The moldboard and chisel shank are mounted as a one-piece unit on the new plow. The moldboard works down to a depth of 12 in. and the chisel can be adjusted from 4 to 8 in. below the leading edge of the moldboard bottom by changing ripping teeth on the end of the shank. When set at an 8-in. depth the shank will be working a total of 20 in. below the surface.

"There are many areas of the country where farmers already make two passes to both chisel and turn the soil while in other areas farmers wish they could do both but can't justify the expense of two pieces of equipment and two passes through the field," says Moore.

The new plow is not available as an add-on unit to existing plows. A 4-bottom unit, with room for expansion to 5 bottoms sells for about $10,000.

For more information, contact: FARM SHOW Followup, M & M Plow & Equipment Mfg. Inc., P.O. Box 831, San Angelo, Tex. 76902 (ph 915 653-7231).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.