1991 - Volume #15, Issue #1, Page #09

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

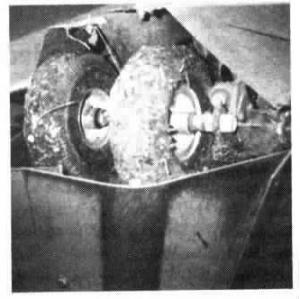

Rubber Tired Soybean Header

|

|

Buyno and Weathers unbolted the steel skid plates they had been using on their Deere 853 8-row 30-in. soybean head and installed the 101/2-in. dia., 2-ply tires. A 6 1/2-in. long, 3/4-in. dia. bolt extends from the spindle of each wheel and is secured by a washer, lock nut, and bushing to mounting brackets made out of old modified anhydrous ammonia knives. The bottom end of each knife is bolted to the same mounting brackets on the header that were used to secure the skid plates.

"The rolling action of the tires works much better than the dragging action of skid plates and keeps the cutting knives from being plugged up by mud and leaves," says Weathers, who has used the tires to harvest soybeans on 1,100 acres each of the past two years. "The tires really work great in the evening when the ground is a little damp but the soybeans are still dry. In these conditions skid plates tend to push soybean stubble and damp leaves along into piles causing the header to drag, whereas our tires roll right over them and let us work later into the evening. We harvested through muddy areas and even some standing water last fall and were able to cut soybeans close to the ground, which would have been impossible with skid plates. The tires also work better than skid plates in rocky ground because they roll right over rocks. We spent about $700 to install the tires." Buyno and Weathers bought the wheels from a lawnmower shop and the tires from a local tire dealer. To make the mounting brackets they cut 4 in. off the bottom end of each anhydrous knife making it 10 1/4-in. long. Two preexisting holes spaced 3 in. apart are used to bolt the bottom end of each knife to the skid plate mounting brackets. One hole was slotted and one hole was round. They used a cutting torch to convert the round hole into a slot. "If we want to apply more down pressure on the tires in order to raise the head higher, we simply loosen the bolts and reposition the brackets," ex-plains Buyno. They torched a 3/4-in. dia. hole in the other end of the knife to attach to the wheel shaft.

Contact: FARM SHOW Followup, Gary Weathers, Rt. 1, Box 228, Ridge Farm, Ill. 61870 (ph 217 247-2948).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.