1981 - Volume #5, Issue #2, Page #07

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

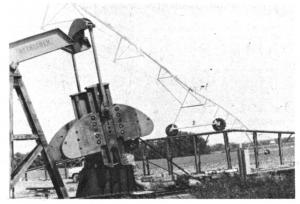

Ramps Lift Center Pivot Over Oil Well

|

The steel ramps were designed and built specifically for Anest, of Bayard, so that he could have his cake and eat it too - oil as well as irrigated crops. His oil well pumps about 40 barrels of crude oil a day and, his irrigated corn last year yielded close to 200 bu. an acre.

"The idea of mixing oil with water works beautifully," Anest told FARM SHOW. "The center pivot rises on the two towers and the oil well is between them. One ramp is 10 ft. high, the other about 14 ft., and the longest ramp is about 140 ft."

"The field measures 50 acres and was worthless $50 an acre land when I bought it," says the Nebraskan. He told Jim Franklin, service manager at Midwest Farm Service in Gering, Neb., that he'd buy a center pivot irrigation system for the field if Midwest could come up with a way to "walk" it over the oil well on each revolution. Midwest is a dealer for Lockwood Corp., a manufacturer of irrigation equipment also headquartered in Gering. Lockwood engineers designed the ramps. No alterations in the center pivot itself were required.

According to Franklin, his company is available to engineer and build similar systems for other farmers for bridging things in fields that can't be moved. Or, a farmer handy with a welder and cutting torch could build one himself to cross ditches, span roads, or whatever.

The sixth and seventh towers of Anest's system cross the ramps, and the sprinkling goes right on. Distance between the two ramps (and two pivot towers) is 148 ft. Both ramps are curved slightly to compensate for the circular movement of the system. The ramps, made out of old sprinkler systems, are secured to the ground by concrete footings. The ramps are 4 ft. wide at the bottom, and 2 ft. wide at the top where the center pivot's wheels travel.

"You can run the system at any speed you want, including wide open," says Arnest. "The ramps don't slow the pivot down at all - electrical power pulls the system right on up and over. They do cause some trouble in that you have to work around them when tilling and harvesting."

Anest's system, including the ramps and the center pivot, cost $40,000. He estimates the ramps themselves cost $7,000 to $8,000. He did none of the work himself.

For more information, contact: FARM SHOW Followup, Midwest Farm Service, Box 366, Gering, Neb. 69341 (ph 308

632-6137).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.