1984 - Volume #8, Issue #3, Page #03

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

You'll Like This All-New Parallel Milking Parlor

|

|

Cows stand parallel to each other for milking and you milk them from behind. "With this system, you can put almost twice as many cows into the space required for a herringbone system," explains Walt.

What's more, two cows are milked with each milking unit, allowing them twice as much time to eat grain.

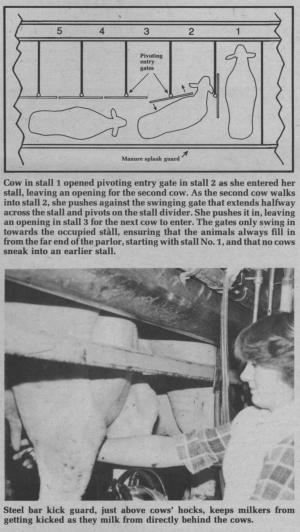

Key to making the system work is the patented method Walt designed for moving cows in and out of the parallel parlor (see drawing).

It ensures that cows enter the stalls in a matter of minutes on their own ù without having to be prodded or coaxed. When all of the cows in an 18 stall parlor, for example, have been milked, the entire unit ù upfront feeding manger and the stall partitions themselves, is raised via an air cylinder allowing all 18 cows to walk out straight ahead. After all the cows are out the unit lowers back into position. The manger automatically reloads with feed and the next batch of cows moves in. "Instead of milkers having to spend 30 to 50% of their time moving cows in and out of the parlor, this system reduces cow moving time to a practically nothing," says Walt.

His brother Jerry De Jong, of Duvall, Wash, installed the first parallel parlor system last fall for his 200 cow herd. He was able to get an 18-cow "parallel" parlor into the same space required for a 10-cow herringbone system.

He's happy with the all-new parlor and reports that his milking crew had no trouble getting used to milking cows from behind.

A "kick" guard, made of a steel bar and positioned just above the cows' hocks, protects milkers from getting kicked. They're further protected from manure and urine by a 28 in. high stainless steel splash guard and gutter. Waste material falls into the gutter and is flushed out after each milking shift.

A single cross auger loads feed into the stainless steel manger running in front of the 18 cows. Feed falls into and fills a 4 in. feeding tube serving each stall. Each cow self-feeds out of the tube in her stall.

"With this system, there's only one motor and one cross auger for all 18 stalls. We can group cows by production and adjust the amount of feed fed per group by adjusting the height of the cross auger. The lower it is, the shorter the tube to each cow and the less feed they get. The simplified system handles all types of grain, even high moisture corn, without plugging problems," says Walt.

He admits that identifying the cows while they're in the parallel parlor is a little trickier than in other parlors. He says ear tags works best and, if the cows' legs stay clean, leg bands work well. He notes that the new parallel milking parlor can replace an existing herringbone system as long as there's at least 94 in. of room between the curb and outer edge of the feeders.

Cost of the new parallel is comparable to putting in a herringbone, says Walt.

For more information, contact: FARM SHOW Followup, De Jong Dairy & Equipment Co., 23430 High Bridge Rd., Monroe, Wash. 98272 (ph 206 788-1025 or 794-7905).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.