1995 - Volume #19, Issue #3, Page #18

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

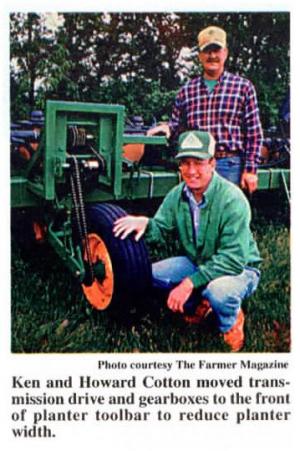

He Narrowed Up New 12-Row Planter

|

Ken and his brother, Howard, bought the planter set up for 22-in. rows, which is standard in sugar beet production and is becoming more popular in corn. A 30-in. planter comes equipped from the factory with the transmission drive and gearbox assemblies mounted between the row units. However, a 22-in. spaced planter comes with the transmission drive and gearboxes mounted on each end of the toolbar which adds an extra 1 1/2 ft. to each side. "The extra 3 ft. of width makes it more difficult to get through some bridges, gates, or through our 24-ft. shop door," says Cotton.

He cut the transmission drive and gear-boxes off each end, then remounted them within steel frames that he mounted on top of the planter toolbar above the depth gauge wheels, which were modified to serve as drive wheels. He lengthened the shaft coming out of the transmission and connected it to a jackshaft that drives six row units. Ratchet sprockets are used to keep the gear-boxes from turning whenever the planter is backed up.

"It works quite well - if I bought another planter I'd do it again," says Cotton. "I spent only about $400 on parts."

Cotton also modified the row markers so that they fold vertically instead of backward and aren't in the way as much, allowing him to plant closer to field edges and fence rows.

Contact: FARM SHOW Followup, Ken Cotton, 316 5th Ave. S.E., Hillsboro, N. Dak. 58045 (ph 701 436-4153).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.