1984 - Volume #8, Issue #3, Page #24

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Missouri Farmers Build Underground Hog Barn

|

|

Rowland Gengelbach and son David began building the barn last year. They came up with the design for the half-circle shaped building and took it to underground building experts who helped perfect the design.

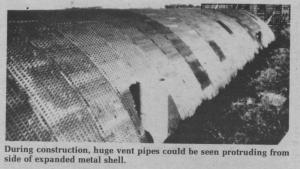

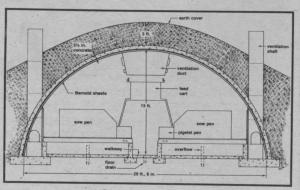

Key to the success of the 60-crate, 150 by 30-ft. farrowing barn is the half-circle design that uses a new expanded metal material made by United States Gypsum, Chicago, Ill. The 1/16-in. thick sheets are set up in a half-circle and 1 1/2-in. of concrete is sprayed on the inside. Then, 5 1/2 in. of concrete is sprayed on the outside. With no further support inside, and 3 to 12 ft. of dirt covering over the sides and top, the building becomes nearly impossible to crush and will support even the heaviest tractors and other equipment driven over the top of it.

The 13-ft. high building features a huge ventilation duct running down the center and big ventilation pipes down either side of the building. Air comes in to the ventilation duct from the open end of the building and is pulled out of it and down to the bottom of the exhaust pipes, where it's blown up above ground. The system will both heat and cool the building.

Below the ventilation duct, the Gengelbach's have installed an automatic feed cart system. The cart operates automatically, running on a track. It feeds sows according to the information on electronic ear tags, obtaining all its information from a central computer.

The Gengelbach's did most of the construction themselves, searching the state for many of the components. Some of the ventilation pipe, for instance is actually 5-ft. sewer pipe that was left over from a construction job. They bought it for a fraction of it's original cost.

The two hog farmers don't expect to have any condensation problem inside, thanks to insulation of the shell and good ventilation. Manure is carried out from underneath the woven wire floors by a gentle flow of water to a 14-ft. deep lagoon at the end of the building.

"If it works out as well as we expect we may build a second underground building right next to it in the near future," Gengelbach told FARM SHOW.

The entire structure, complete with pens, wiring and other facilities, cost the Gengelbach's about $138,000, not including their own labor and the computerized feeder. Plans and a list of materials are available from the United States Gypsum company.

For more information, contact: FARM SHOW Followup, United States Gypsum, 101 South Wacker Drive, Chicago, Ill. 60606 (ph 312 321-5786).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.