1993 - Volume #17, Issue #2, Page #03

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

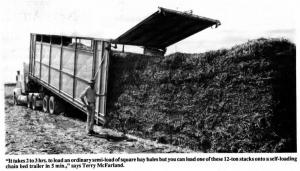

Baler Makes 12 Ton Bales

|

Terry McFarland, who operates out of Narrabri in New South Wales, uses a cotton module builder to make the big stacks, which contain the equivalent of 500 to 600 small square bales. Cotton module builders are used all over the world to make the big stacks of cotton which are standard for that crop.

McFarland says his giant bales have many advantages over their smaller cousins, particularly when it comes to pricing and handling. For a start, he's able to sell them for much less because of the reduced labor required to stack and handle the giant stacks.

"It takes 2 to 3 hours to load an ordinary semi-load of hay bales but you can load one of these stacks onto a self-loading chain bed truck in 5 min.," he points out noting that, at least in his part of Australia, there are plenty of chain bed trucks around looking for work so he hasn't had to buy one. And cotton module builders are only used during cotton harvest so they're free for hay work the rest of the year.

McFarland cuts and bales hay into big stacks in the summer and leaves them in the field with a tarp over the top until someone places an order. "Rain doesn't hurt them. They're virtually a self-contained hay shed," he says.

He cuts and chops hay or sorghum stubble or whatever he's baling with a forage harvester and blows it into high-dump wagons (also used for handling cotton) which then dump the hay into the cotton press. It takes 10 to 15 acres and about 2 hours to make each bale. On average, his crew of five makes 5 to 6 bales a day.

"People were very skeptical at first but it's just a matter of them getting used to a new idea," says McFarland. "They said the bales wouldn't hold together on the trucks but we've transported 20 of them and they hang together better than cotton modules."

Feeding the hay out is not a problem, he says. Some buyers just plunk big bales down in the pasture and let animals feed off them from all sides. Others put a fence around the bales and let stock feed from on end with a self-feed gate. Others use loader forks to break chunks off the bale to carry t livestock.

Contact: FARM SHOW Followup, Ten McFarland, Wandahlee, Narrabri, 2390 Nel South Wales, Australia.

(Reprinted with permission from THE LAND Magazine)

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.