1980 - Volume #4, Issue #5, Page #14

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Cowpower: New Energy Source For The 80s

|

"You can heat a 2,000 sq. ft. house with the heat from just 15 cows," says Brian Ramlow, of Atmospheric Energy Systems, the Madison, Wis., company which developed "Cowpower".

"Every cow produces 3,500 to 4,000 btu's of body heat per hour. Unfortunately, most of this heat is dumped outside by ventilating fans where it's no good to anyone. We found a way to use that heat," Ramlow told FARM SHOW.

The only Cowpower installation in operation so far is a pilot unit set up for dairyman David Thiele, of DeForest, Wis. Thiele uses the Cowpower to heat a calf barn adjacent to his dairy barn.

"We installed the system last December to heat our calf barn. The previous winter, I was using $200 worth of LP a month. Last winter, we used less than $100 worth of electricity to run the Cowpower unit."

Cowpower is based on proven heat transfer principles. One 5-ft. and two 3-ft. long heat absorber panels, equipped with radiator-like cores, hang from the ceiling to collect the warm, cow-heated air.

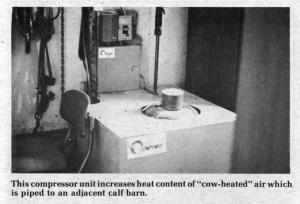

Small fans on each panel help draw in the heat which is then transferred to a compressor or series of compressors, depending on size of the system. The compressor amplifies the amount of heat in the air by as much as one third in much the same way a diesel engine heats up its fuel-air mixture with compression. Cowpower air is heated in excess of 140?.

At that point, heat is transferred to a freon compound which is piped through insulated copper tubing to Thiele's calf barn. There, a heat exchanger removes the heat from the freon and blows it out to the calves.

"One unexpected advantage of this system is that the heat is dry and seems to keep the calves healthier," says Ramlow. "Also, since the heat absorbers takee just the heat out of moistened air the excess moisture is condensed on the coils and can be drained away, making the dairy barn a healthier place. Since freon transmits only heat, moisture cannot be transferred."

Do cows overheat, or get chilled, when tapped for Cowpower?

"The temperature in the dairy barn rarely dropped more than a degree or two with the Cowpower system operating," answers Thiele. "Most of the heat we harness would be lost through the ventilating fans anyway.

"We could even let the cows out to exercise a couple of hours a day without a significant loss of heat, except in extremely cold weather. We also noticed that we could shut down a couple of the ventilating fans when the Cowpower was working. That practically saves as much electricity as the Cowpower motors and compressor consumes," Thiele adds.

Ramlow says his company is researching the use of Cowpower with other animals. "Hogs raised in confinement show some promise as a heat source, but poultry and most other animals probably don't produce enough excess heat to make this system feasible."

Thiele's prototype Cowpower system cost about $8,500 and may be eligible for the 40% tax break available for solar and other alternative energy systems.

The company is now taking orders on three models, ranging from 67,000 to 87,000 btu's.

"A house-sized system needs about 15 cows and four of the 5-ft. long absorber panels. The heated freon can be piped up to 300 ft. and adapted tc any type of home heating system with the use of heat exchangers," Ramlow says.

For more information, contact FARM SHOW Followup, Atmospheric Energy Systems, 909 E Stewart St., Madison, Wis. 53713 (ph 608 271-1692).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.