1989 - Volume #13, Issue #6, Page #09

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Pickup Mounted Air Compressor

|

The idea was first published in GRAINEWS magazine in Canada. It stirred up a lot of interest and Hagen is still responding to farmers who had questions about how his compressor works.

"It has volume to compare to a 2-hp. commercial air compressor. I use it to pump tires and to run air tools, spray painters, foam markers, and other equipment," says Hagen.

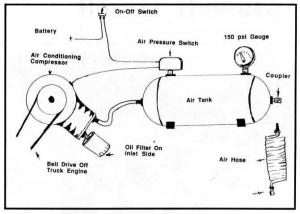

He simply mounts an old air conditioner pump on his pickup engine and pumps air to a 2-gal. holding tank behind the seat. He notes that the holding tank could just as well be mounted under the hood if there was room.

The electric clutch on the air conditioner pump is engaged by a toggle switch on the dash and controlled by a pressure switch on the tank so it's fully automatic. When you flick the switch on he says you have up to 100 psi air. At highway speeds Hagen says the compressor will go from 0 psi to 100 psi and then shutoff automatically in less than 15 sec. "It's much faster than a 3/4-hp. shop compressor and it doesn't spoil the truck's looks at all. It can be removed from the truck in less than 1/2 hr.," says Hagen. "I hardly use my shop compressor now because this one is so fast. I've used it for five years with no problem."

The one question everyone asks is how he lubricates the compressor. Air conditioner compressors are normally lubricated by the oil that circulates with the refrigerant. The pistons on the compressor do not have oil rings for oil control so most mechanics assume that the oil will just pump out past the rings and mix with the air but Hagen says he doesn't modify the compressor at all. He simply keeps the oil compartment filled with regular motor oil. Only small traces of oil go through the system, he says. He puts an oil filter on the inlet side of the the com-pressor and a short air hose on the outlet side. Normally, he says, you have to rig up special fittings to fit the compressor. Then you mount the compressor on the side of the truck engine the way any air conditioning compressor would be mounted.

Herb Killn, a Strasbourg, Sask., farmer who read Hagen's original article in GRAINEWS, put a Chrysler compressor on his Dodge pickup. "I put oil in the compressor and check it regularly. There never seems to be oil in the compressed air. My son used the compressor to paint my 18-ft. stock trailer. The only problem we had is that after 1/2 hr. of continuous use the compressor gets very hot. When he finished painting and the compressor had cooled down, I checked the oil and had to add only about 2 ounces. That's after about 2 hrs. use."

Contact: FARM SHOW Followup, Wayne Hagen, Box 215, Lake Alma, Sask. S0C 1M0 Canada (ph 306 447-4721).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.