Rock Picker Mounts On Self-Propelled Swather

✖  |

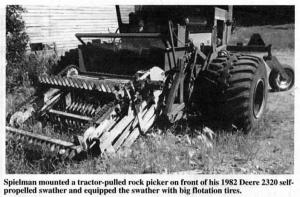

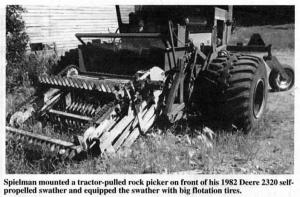

Once a field has been seeded with small grains, it's virtually impossible to get back into it to pick up rocks without doing a lot of damage, unless you pick them out by hand. Mark Spielman, Twin Valley, Minn., got around the problem by mounting a tractor-pulled rock picker on the front of his 1982 Deere 2320 self-propelled swather and equipping the swather with big flotation tires. When he's done picking rocks the swather converts back for harvest.

It lets me pick up rocks in newly seeded fields without digging ruts and I have a much better view of the rock picker in front of me," says Spielman.

Spielman bought a used 5-ft. wide Schulte pull-type rock picker for $5,000. It was designed so that the conveyor could be either pto-driven or operated by an orbit motor. He welded the orbit motor onto the picker, then mounted the picker on a homemade 5-wide, 30-in. high steel basket that attaches to the header mounts. The orbit motor is powered by an add-on hydraulic pump that's pto-driven off the swather. The motor powers a hydraulic cylinder that's used to raise or lower the picker. Spool valves in the cab are used to operate the cylinder and to control forward-reverse direction of the conveyor (push-pull control cables connect the valves to the pump and motor). He also replaced the swather's original front tires with 31-in. wide flotation tires on 20-in. wheel rims.

It lets me pick up rocks in newly seeded fields without digging ruts and I have a much better view of the rock picker in front of me," says Spielman.

Spielman bought a used 5-ft. wide Schulte pull-type rock picker for $5,000. It was designed to be either pto-driven or operated by hydraulics. He welded a hydraulic motor onto the picker, then mounted the picker on a homemade 5-wide, 30-in. high steel rock basket that attaches directly to the swather in place of the header. The hydraulic motor is powered by an add-on hydraulic pump that's pto-driven off the swather. A hydraulic cylinder raises or lowers the picker. Spool valves in the cab are used to operate the cylinder and to control forward-reverse direction of the conveyor. Spielman replaced the swather's original front tires with 31-in. wide flotation tires on 20-in. wheel rims.

It does so little damage to fields that I've even used it when grain is up and in the 2 to 3 leaf stage. It's easy to see the rocks against the green grain. I can hardly see where I went. I put depth stops on the hydraulic cylinder to keep the rock picker from digging too deep. I got the idea after I bought a new Deere air seeder with 10-in. wide sweeps that bring up a lot of rocks. I'm often surprised at how many rocks I find. I might go out in the field thinking there's a basket full and end up filling four or five baskets.

I also use it before seeding hay fields. The mower conditioner I use to cut hay throws rocks like 90 mph fastballs. I had three tractor windows broken by flying rocks.

"The rock basket between the picker and the swather slopes down at the bottom and has a door on back. To dump rocks, I pull on a rope inside the cab that's attached to a lever at the bottom of the door. It swings the door back and down. Once the door is open I slowly drive ahead to empty out the rocks. The biggest disadvantage is that it won't dump rocks into a pile. I have to leave them in a layer at the end of the field or on a driveway, etc., then later use a skid steer loader to pile them up.

Contact: FARM SHOW Followup, Mark Spielman, Rt. 1, Box 142, Twin Valley, Minn. 56584 (ph 218 567-8510).

Click here to download page story appeared in.

Click here to read entire issue

Rock Picker Mounts On Swather ROCK PICKERS Rock Pickers 19-5-3 Once a field has been seeded with small grains, it's virtually impossible to get back into it to pick up rocks without doing a lot of damage, unless you pick them out by hand. Mark Spielman, Twin Valley, Minn., got around the problem by mounting a tractor-pulled rock picker on the front of his 1982 Deere 2320 self-propelled swather and equipping the swather with big flotation tires. When he's done picking rocks the swather converts back for harvest.

It lets me pick up rocks in newly seeded fields without digging ruts and I have a much better view of the rock picker in front of me," says Spielman.

Spielman bought a used 5-ft. wide Schulte pull-type rock picker for $5,000. It was designed so that the conveyor could be either pto-driven or operated by an orbit motor. He welded the orbit motor onto the picker, then mounted the picker on a homemade 5-wide, 30-in. high steel basket that attaches to the header mounts. The orbit motor is powered by an add-on hydraulic pump that's pto-driven off the swather. The motor powers a hydraulic cylinder that's used to raise or lower the picker. Spool valves in the cab are used to operate the cylinder and to control forward-reverse direction of the conveyor (push-pull control cables connect the valves to the pump and motor). He also replaced the swather's original front tires with 31-in. wide flotation tires on 20-in. wheel rims.

It lets me pick up rocks in newly seeded fields without digging ruts and I have a much better view of the rock picker in front of me," says Spielman.

Spielman bought a used 5-ft. wide Schulte pull-type rock picker for $5,000. It was designed to be either pto-driven or operated by hydraulics. He welded a hydraulic motor onto the picker, then mounted the picker on a homemade 5-wide, 30-in. high steel rock basket that attaches directly to the swather in place of the header. The hydraulic motor is powered by an add-on hydraulic pump that's pto-driven off the swather. A hydraulic cylinder raises or lowers the picker. Spool valves in the cab are used to operate the cylinder and to control forward-reverse direction of the conveyor. Spielman replaced the swather's original front tires with 31-in. wide flotation tires on 20-in. wheel rims.

It does so little damage to fields that I've even used it when grain is up and in the 2 to 3 leaf stage. It's easy to see the rocks against the green grain. I can hardly see where I went. I put depth stops on the hydraulic cylinder to keep the rock picker from digging too deep. I got the idea after I bought a new Deere air seeder with 10-in. wide sweeps that bring up a lot of rocks. I'm often surprised at how many rocks I find. I might go out in the field thinking there's a basket full and end up filling four or five baskets.

I also use it before seeding hay fields. The mower conditioner I use to cut hay throws rocks like 90 mph fastballs. I had three tractor windows broken by flying rocks.

"The rock basket between the picker and the swather slopes down at the bottom and has a door on back. To dump rocks, I pull on a rope inside the cab that's attached to a lever at the bottom of the door. It swings the door back and down. Once the door is open I slowly drive ahead to empty out the rocks. The biggest disadvantage is that it won't dump rocks into a pile. I have to leave them in a layer at the end of the field or on a driveway, etc., then later use a skid steer loader to pile them up.

Contact: FARM SHOW Followup, Mark Spielman, Rt. 1, Box 142, Twin Valley, Minn. 56584 (ph 218 567-8510).

To read the rest of this story, download this issue below or click

here to register with your account number.