1986 - Volume #10, Issue #1, Page #25

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Farmer Converts Grain Drill To Band Fertilizer

|

|

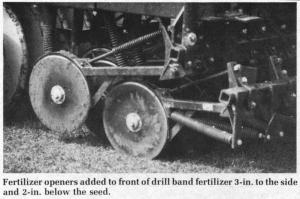

As set up originally, fertilizer on the 40-run, 6-in. spaced drill dropped down a separate tube just in front of the seed in the same furrow. Now, with the 1-ft. spaced disc openers in place, fertilizer is banded 3 in. to the side and 2 in. below the seed.

To make the conversion, the farmers bought the same openers and mounting brackets that the Morris drill was fitted with and built a frame just ahead of the seed openers. The add-on frame is attached in such a way that it raises out of the ground with the openers. The fertilizer tubes were simply rerouted to the new fertilizer units. Depth of fertilizer placement is adjusted by adding or removing washers on the hydraulic cylinder. Each banding disc has 110 lbs. of down pressure. The only problem experienced was plug-ups when seeding wet low spots. The men plan to rework the mountings on the front fertilizer openers to make more clearance between the ground and the springs.

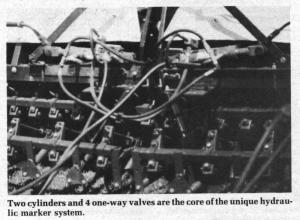

The Hacaults also equipped the drill with unique hydraulic markers. "We built the markers with two cylinders and four one-way relief valves. Each cylinder has one low pressure one-way relief valve and one high-pressure one-way relief valve. Both cylinders are connected together in such a way that the marker that is on the ground raises to the end before the other marker moves. Both markers stay in transport position by releasing the hydraulic lever when both markers are up. When the tractor hydraulic lever is engaged, oil flows to the cylinder that is extended, retracting it. When the cylinder is retracting, the oil on the other side of the plunger is forced through a low pressure one-way valve back to the tractor. When the cylinder is retracted to the end, the oil is diverted to the other cylinder through a high-pressure one-way valve, extending it and dropping the other marker," explains Albert.

For more information, contact: FARM SHOW Followup, Edward & Albert Hacault, Bruxelles, Manitoba R0G 0G0 Canada (ph 204 526-2495).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.