1980 - Volume #4, Issue #2, Page #08

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

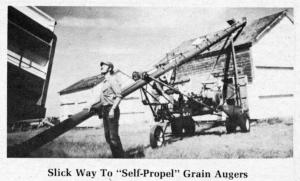

Slick Way To Self-Propel Grain Auger

|

Not so at the Burton Farm at Vanguard, Sask., Canada. Their big 54 ft. long grain auger with an 8 in. screw can be raised and lowered by the touch of a lever and it can be moved just as easily.

That's because they mounted the auger on the chassis of an old Versatile self-propelled windrower and used the machine's engine and hydraulics to do the work.

"It's versatile - the windrower can be turned on a dime - and is easily placed into position at the granary." Ralph Burton told Farm Show.

The hydraulic system used to raise and lower the windrower table is used to raise and lower the auger. One man can easily handle the big auger and place the end of it in the filler hole at the top of the bin. ~Vhen the bin is full, it's just as easy to lift the auger spout out of the filler hole and relocate the auger at another site.

Even moving the loader from one farmstead to another is fast. At all times, the loader is under complete control. it can be lowered so it is parallel to the ground which keeps it fairly low so it moves under power lines and telephone wires," explains Ralph.

To mount the heavy auger and still keep the load balanced, the swather frame had to be modified and the wheel repositioned so the auger could be mounted directly between the two drive wheels.

The original sickle drive is used to power the auger. The drive to the auger caused some problems. Getting the mounting right to reduce wear on the drive belt was the worst," explains Ralph. After several attempts, he and his nephew David solved the problem by dropping the hangers on which the loader is mounted on the windrower by a couple of inches. We ended up with a V-belt drive that won't squeak and rattle when the auger is under load." David points out.

For more information, contact: Farm Show Followup, Ralph Burton, Vanguard, Sask., Canada (ph 306 582-6128).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.