1990 - Volume #14, Issue #4, Page #34

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

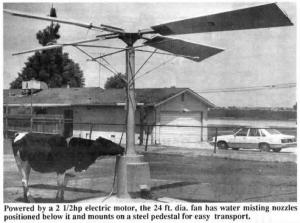

Giant Fan Keeps Feedlot Cattle Cool

|

The University of California extension researcher has designed a barnyard version of overhead paddle fans used in homes and offices. His fan is 24 ft. in dia. from blade tip to blade tip and has water misting nozzles positioned below it.

The fan, which mounts on a steel pedestal and can be moved easily from place to place, is powered by a 2 1/2 hp. electric motor. "It spins slow at about 44 rpm's but blade tip speed is the same as on a 48-in. dia. fan," says Fairbank, who says the optimum speed may be even slower at about 36 rpm. This is the second summer that the giant fan is in testing.

With a power consumption of just 2 watts per hour, the fan costs just 10 to 30 cents per hour to run, depending on local electrical costs. The motor direct-drives the fan through a 38.4:1 gearbox. The fan, which weighs 1,200 lbs., can be picked up by a front-end loader. It requires only electrical hookup to 110 volts and connection to a water hose with normal water pressure. The 2-in. dia. center pipe carries electrical and water lines.

There are four mister arms positioned just below the fan blades. Each arm is fitted with two 1.5 gpm nozzles for a total water requirement of 12 gpm.

"It can be positioned anywhere. One fan will cool approximately 100 head of cattle. The slow speed fan provides just as much cooling as higher speed fans. Some animals don't like fast-moving airstreams," says Fairbank. He says that in testing he's found that the fan can eliminate feeding problems caused by hot weather. The fan can be positioned next to dip pens, in runways between corrals or under shade areas.

The lightweight blades are 1 3/8-in. thick with a wood frame and a foam-filled inner cavity. Each blade weighs less than 40 lbs. Because the blades spin so slowly, their design does not have to be aerodynamically perfect.

Fairbank expects each fan to cost around $6,000. He says that compares favorably with other commercial cooling systems that can cost as much as $50,000. He can pro-vide literature on his prototype models or refer interested readers to the manufacturer he's been working who will build fans on a custom basis.

For more information, contact: FARM SHOW Followup, Bill Fairbank, University of California, 1151 Geology Building, Riverside, Calif. 92521 (ph 714 787-3333 or 3710).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.