Home Built 4WD Articulated Tractor

"It does the job of a state-of-the-art $180,000 tractor at a fraction of the cost," says Mervin Laughlin, Youngstown, Alberta, happy with his home-built 425-hp 4-WD articulated tractor that's modeled after the RITE 4-WD tractors built in Montana and Canada.

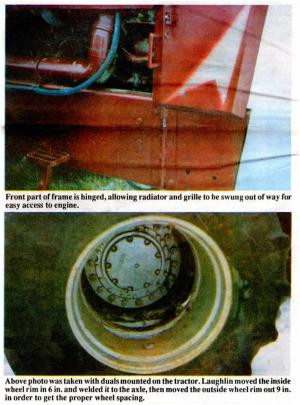

Laughlin used the frame and cab from a 1983 Massey 4900 tractor and a Caterpillar 3406 diesel engine and 15-speed transmisĦsion out of a 1982 Freightliner semi tractor. He stripped the tractor down to the frame and cab and lengthened the frame 15 in. in order to make room for the bigger engine. He mounted two Clarke 70,000-lb. planeĦtary rear axles on the frame along with a Clarke transfer case. He had a machine shop make new centers on Massey wheel rims to match the Clarke axles.

"It really works great and has a lot of power. I used it last year to pull my 56-ft. air seeder and 72-ft. field cultivator," says Laughlin, who built the tractor with help from sons Jeff and Tim and friend Billy Powell. "I built it because the Cummins V-8 diesel engine on the Massey tractor was worn out and I wanted more power. The Clarke planetary rear axles are the type used on big earth-moving and logging trucks, so they're built very heavy. It doesn't look like a rebuilt tractor. I took it to a farm show last year, and a lot of people thought it was factory-built.

"One nice feature is that the front part of the frame is hinged, allowing the radiator and grille to be swung out of the way for easy access to the engine. I hinged one side

of the frame and secured the other side with eight bolts."

The gear shift lever on the truck transmission was mounted in the middle of the transmission and would have come up through the center of the cab floor. Laughlin rebuilt the linkage so that the shift lever could be moved to the right side of the cab. He remounted the Massey air filter on the new engine and moved the exhaust pipe to the side for better visibility.

The driveline on the Massey tractor had a bearing between the transmission and rear axle that vibrated badly. Laughlin removed the bearing and used a length of drill stem to make twin bearings that are centered on the driveline. "They work perfectly," notes Laughlin, who paid $9,500 for the semi tractor and $12,000 for the Clarke axles and transfer case.

For more information, contact FARM SHOW Followup, Mervin Laughlin, Box 23, Youngstown, Alberta Canada TOJ 3P0 (ph 403 779-2188).

Click here to download page story appeared in.

Click here to read entire issue

Home built 4WD articulated tractor TRACTORS Made-It-Myself 17-3-40 "It does the job of a state-of-the-art $ 180,00O tractor at a fraction of the cost," says Mervin Laughlin, Youngstown, Alberta, happy with his home-built 425 hp 4-WD articulated tractor that's modeled after the RITE 4-WD tractors built in Montana and Canada

Laughlin used the frame and cab from a 1983 Massey 4900 tractor and a Caterpillar 3406 diesel engine and 15-speed transmisĦsion out of a 1982 Freightliner semi tractor. He stripped the tractor down to the frame and cab and lengthened the frame 15 in. in order to make room for the bigger engine. He mounted two Clarke 70,000-lb. planeĦtary rear axles on the frame along with a Clarke transfer case. He had a machine shop make new centers on Massey wheel rims to match the Clarke axles.

"It really works great and has a lot of of power. I used it last year to pull my 56-ft. air seeder and 72-ft. field cultivator," says Laughlin, who built the tractor with help from sons Jeff and Tim and friend Billy Powell. "I built it because the Cummins V-8 diesel engine on the Massey tractor was worn out and I wanted more power. The Clarke planetary rear axles are the type used on big earth moving and logging trucks so they're built very heavy. It doesn't look like a rebuilt tractor. I took it to a farm show last year and a lot of people thought it was factory-built.

"One nice feature is that the front part of the frame is hinged, allowing the radiator and grille to be swung out of the way for easy access to the engine. I hinged one side

of the frame and secured the other side with eight bolts."

The gear shift lever on the truck transmisĦsion was mounted in the middle of the transmission and would have come up through the center of the cab floor. Laughlin rebuilt the linkage so that the shift lever could be moved to the right side of the cab. He remounted the Massey air filter on the new engine and moved the exhaust pipe to the side for better visibility.

The driveline on the Massey tractor had a bearing between the transmission and rear axle that vibrated badly. Laughlin removed the bearing and used a length of drill stem to make twin bearings that are centered on the driveline. "They work perfectly," notes Laughlin, who paid $9,500 for the semi tractor and $12,000 for the Clarke axles and transfer case.

For more information, contact FARM SHOW Followup, Mervin Laughlin, Box 23, Youngstown, Alberta Canada TOJ 3P0 (ph 403 779-2188).

To read the rest of this story, download this issue below or click

here to register with your account number.