Michigan Farmer Builds Giant Manure Spreader

"There's nothing on the market like it," says Michigan farmer Case De Kryger, of Holland, who had a farmer friend custom build him a giant-size liquid manure spreader that holds a whopping 5,100 gals., has a rated capacity of 20 tons, and unloads in only 5 min.

"We've got just over $40,000 invested in it. The closest commercial unit to it in size costs four times as much and has considerably less capacity," notes De Kryger whose friend Wayne Vogel, of Fremont, Mich., built the huge spreader in just two months time.

FARM SHOW readers may remember Vogel, who built his own articulated combine from the ground up. He was featured last year in FARM SHOW's Vol. 7, No. 3 issue.

"The spreader's 5,100 gal. tank was built as an experimental model by Badger. The spreader is completely hydraulic and is electrically controlled from the cab. Even the rear injector toolbar raises and lowers with the press of a button," explains De Kryger.

The chassis of the spreader is the main frame from an 8-ton crane carrier. Vogel stripped off the crane, cab, engine and wheels, leaving only the carrying rails. The first modification was to extend the rear axle to accommodate dual tractor wheels. Tractor tires were also mounted on front. The cab, engine and transmission all came from a GMC semi-truck. The spreader has a 1,200 gal. per min. pump that's hydraulically-driven and primes itself in 15 to 20 sec. A toolbar in back carries 5 shanks for injecting and there is a separate manifold for broadcast spreading when necessary. A 60-hp., pto-driven hydraulic pump powers the manure spreader and controls a 9-in. auger which runs the length of the manure tank, agitating the slurry once it's loaded. The engine is a 300 Detroit diesel and the transmission has 30 speeds. The crane chassis was equipped with a 50,000 lb. load capacity running gear that, De Kryger says, was in "like new" condition. The truck runs at speeds up to 45 mph on the road.

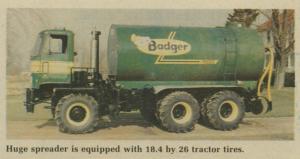

"Even though it weighs as much as 35 tons loaded, we think it causes less compaction than smaller machines due to the large tires," says De Kryger, noting that, so far as he knows, the spreader is the largest ever built.

Vogel, who did all the building of the spreader, has another set of crane carrier running gears and may build a second spreader. He is well-known to farmers in his area for building almost all his own equipment, including combines, self-propelled planters, vegetable harvesters and planters, self-propelled grain wagons, tillers, and more.

De Kryger uses the spreader on his own farm and does custom work for neighbors, charging about 1 cent per gal. spread.

For more information, contact: FARM SHOW Followup, Case De Kryger, 15 Lakeside Dr. S.E., Grand Rapids, Mich. 49516 (ph 616 458-8216).

Click here to download page story appeared in.

Click here to read entire issue

Michigan Farmer Builds Giant Manure Spreader MANURE HANDLING Equipment 8-4-21 "There's nothing on the market like it," says Michigan farmer Case De Kryger, of Holland, who had a farmer friend custom build him a giant-size liquid manure spreader that holds a whopping 5,100 gals., has a rated capacity of 20 tons, and unloads in only 5 min.

"We've got just over $40,000 invested in it. The closest commercial unit to it in size costs four times as much and has considerably less capacity," notes De Kryger whose friend Wayne Vogel, of Fremont, Mich., built the huge spreader in just two months time.

FARM SHOW readers may remember Vogel, who built his own articulated combine from the ground up. He was featured last year in FARM SHOW's Vol. 7, No. 3 issue.

"The spreader's 5,100 gal. tank was built as an experimental model by Badger. The spreader is completely hydraulic and is electrically controlled from the cab. Even the rear injector toolbar raises and lowers with the press of a button," explains De Kryger.

The chassis of the spreader is the main frame from an 8-ton crane carrier. Vogel stripped off the crane, cab, engine and wheels, leaving only the carrying rails. The first modification was to extend the rear axle to accommodate dual tractor wheels. Tractor tires were also mounted on front. The cab, engine and transmission all came from a GMC semi-truck. The spreader has a 1,200 gal. per min. pump that's hydraulically-driven and primes itself in 15 to 20 sec. A toolbar in back carries 5 shanks for injecting and there is a separate manifold for broadcast spreading when necessary. A 60-hp., pto-driven hydraulic pump powers the manure spreader and controls a 9-in. auger which runs the length of the manure tank, agitating the slurry once it's loaded. The engine is a 300 Detroit diesel and the transmission has 30 speeds. The crane chassis was equipped with a 50,000 lb. load capacity running gear that, De Kryger says, was in "like new" condition. The truck runs at speeds up to 45 mph on the road.

"Even though it weighs as much as 35 tons loaded, we think it causes less compaction than smaller machines due to the large tires," says De Kryger, noting that, so far as he knows, the spreader is the largest ever built.

Vogel, who did all the building of the spreader, has another set of crane carrier running gears and may build a second spreader. He is well-known to farmers in his area for building almost all his own equipment, including combines, self-propelled planters, vegetable harvesters and planters, self-propelled grain wagons, tillers, and more.

De Kryger uses the spreader on his own farm and does custom work for neighbors, charging about 1 cent per gal. spread.

For more information, contact: FARM SHOW Followup, Case De Kryger, 15 Lakeside Dr. S.E., Grand Rapids, Mich. 49516 (ph 616 458-8216).

To read the rest of this story, download this issue below or click

here to register with your account number.