1978 - Volume #2, Issue #3, Page #23

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

Slickest Farrowing Setup We've Seen

|

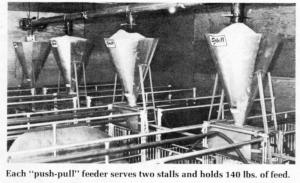

"We built the first prototype on our own farm four years ago and have used it ever since. We know it works," Delmar told FARM SHOW. Heart of the new-style farrowing house is a patented, first-of-its-kind "push-pull" limit feeder which Lynch himself invented and is having produced commercially under a licensing agreement with a local manufacturer. You can bury it separately to update an existing farrowing setup, or as part of the complete "turnkey" 10-sow farrowing house which the Lynchs have introduced under the name Sydell Systems.

The most attractive feature of the innovative 10-sow farrowing setup (20 x 28 ft.) is its price tag - an average of right at $1,150 per sow for the complete package, including the building, equipment, manure pit and labor. At today's inflated prices, that price is tough to beat. What's more, it only takes one man about 15 seconds to do the sow-feeding chores twice a day.

The Lynchs cut costs considerably with a unique design innovation. Their farrowing house has an aisle along each side (no center aisle), and an aisle along one end of the building. The 10 farrowing crates butt head to head, five on each side. "We were able to reduce width from 26 to 20 ft. by eliminating the center aisle," says Delmar, who operates a 300-sow operation.

Holding width to 20 ft. allowed him to get by with an undivided, clear span manure pit, which cut concrete costs almost in half. By putting sows head to head, he gets by with only one water line. And, thanks to the unique design of the patented push-pull feeder, one feeder serves two pens, another significant cost savings.

Each feeder holds 140 lbs. and can be set to dispense from 31/2 to 41/2 lbs. of dry feed per feeding per sow. One pull of a single lever which controls the entire lineup of five feeders feeds five sows on the left side. A second pull feeds those on the right side. If size of sows varies, smaller sows can go into stalls on one side, and larger sows on the other. The feeders can then be set so each sow can get a different amount of feed (within a range of 31/2 to 41/2 lbs.) Operation of the push-pull feeders is entirely mechanical - no motors, electric metering mechanism or other complicated parts to adjust or replace. And, the amount of feed per sow per feeding is exactly the same every time - regardless of who does the feeding.

In summer, two thermostatically controlled fans cool the building. A timer-controlled 16 in. fan ventilates the building year-around. The 21 ft. deep pit holds about 10,000 gal. and is emptied about once every 4 months.

"Wouldn't a 10-sow farrowing house be too small for most larger hog producers?

"I'd much rather have two 10-sow units than a single 20-sow facility," explains Lynch. "You get better disease control and the chances of keeping a 10-sow house at 80% or better capacity are much better than trying to keep a larger facility at 80% capacity. This is important in terms of 'apitalizing on heat given off by the sows themselves to cut energy costs. We figure we cut heating costs 30% or more."

Here's a breakdown of costs for the new Sydell Systems 10-sow 20 by 28 ft. farrowing facility:

Building with foundation and manure pit sells for $5,616, plus right at $3,000 for labor. Ten "Sow Joy" crates, manufactured by H and S Mfg., Hospers, Iowa, slats and waterers at $2,000. Five 2-hole Sydell lactation feeders with handle, connecting rods and auger system for filling the feeders at $968. Total estimated cost for the "turnkey" package, including labor, is right at $11,584.

Sydell Systems also offers the new patented feeder in an 8-hole model for limit feeding gestating sows at $548.50. Individual 2-hole (to serve two farrowing crates) Sydell lactation feeders retail for $113.60.

For more details, contact: FARM SHOW Followup, Sydell Systems, Box 89, Burbank, So. Dak. 57000 (ph 605-624-4538).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.