2025 - Volume #49, Issue #5, Page #25

[ Sample Stories From This Issue | List of All Stories In This Issue | Print this story

| Read this issue]

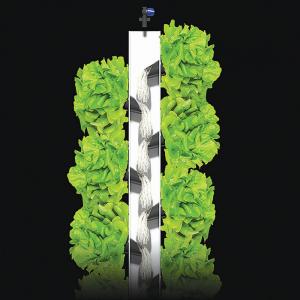

Vertical Carousel Towers Boost Greenhouse Production

|

Chris and Vincent van der Gaag’s Dutch Lion system uses vertical towers on a monorail carousel. Each double-sided tower is composed of panels that are automatically seeded and then raised into a vertical position.

“The towers can be up to 6 m in height (nearly 20 ft.),” says Steinar Henskes, Dutch Lion. “Introductory crops were lettuce and other greens, but we’re also working with strawberries and developing the system for them.”

Towers first move to the germination room and later to their scheduled lane in the greenhouse. When it’s time to harvest the plants, the towers move down their monorail to be emptied, cleaned and reseeded.

A system was installed this past fall at the World Horti Center in Naaldwijk, Netherlands. It consists of four monorails, each supporting 30 cultivation towers. Each tower held 42 heads of lettuce, but had the capacity for up to 60.

The automated system eliminates pathways. The towers automatically move apart as plants grow. As a result, it reduces the needed footprint for a given production level by 90%. This reduces capital expenditure on infrastructure costs by 40% compared to conventional greenhouses.

“As little as 20 sq. m (215 sq. ft.) can be economically efficient,” reports Henskes. “Because the system is modular, it’s custom-designed for every customer.”

Ambient light is diffused from above and supplemented with dynamic LED lighting as needed. Sensors measure light levels and adjust the LEDs to ensure adequate light reaches lower plants. This reduces energy consumption compared to fully enclosed, indoor farms.

Water is also conserved as the growth cycle can be split into multiple irrigation phases. Drippers deliver specific amounts of water and nutrients for optimal growth. The drippers are positioned at the top of the towers, with excess liquids recovered at the base for recirculation. The company reports up to 70% less water used compared to horizontal mobile guttering systems.

Advanced airflow injection ensures even temperature distribution. Air hoses maintain balanced temperatures between the top and bottom sections of the towers. The high circulation rate, air filters, and positive pressure reduce the risk of disease and remove the need for pesticides.

The system is quickly proving itself with initial installations, notes Henske.

“We have had significant interest in the U.S with more projects being commissioned later this year,” he says. “We’re currently looking for partners to help us grow in the North American market.”

Contact: FARM SHOW Followup, Dutch Lion, Katwijkerlaan 67b, 2641PD Pijnacker, The Netherlands (ph +31 85 800 8801; info@dutchlionag.tech; www.dutchlionag.tech).

Click here to download page story appeared in.

Click here to read entire issue

To read the rest of this story, download this issue below or click here to register with your account number.