Electric-Powered Farm Pickup

"We were standing outside the hog house one morning this spring, visiting, when this vehicle just sneaked up alongside us. The only hint we had that anything at all was coming up the driveway was the sound of gravel crunching underneath the tires," says Delaine Listamann about his neighbor, Paul Dozler, whose pickup runs on electricity.

"It's really ingeniously designed," Listamann says. "It's out of this world."

Dozler, who farms near Denison, Iowa, says recent developments in electric power technology make converting cars, pickups - possibly tractors - more practical than ever.

"I was going to convert a car to run on electricity 10 years ago, but the technology then was `Stone Age' compared to now," he explains.

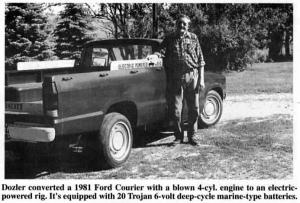

Dozler, who is a member of the Electric Auto Association (2710 St. Giles Lane, Mountain View, Calif. 94040), found a 1981 Ford Courier with a blown 4-cyl. engine. He bought the truck, which had more than 150,000 miles on it, for $500 from an area auto dealer. He started converting the truck last fall and had it on the road by spring, running 100% on electricity.

"It cruises along nicely at 55 mph and can do 65 mph or a little better," Dozler says. "But the faster you go, the less mileage you get out of a charge. Traveling at 40 to 45 mph, you can go 50 miles between charges. Recharging takes about six hours using a 110-volt charger that I stepped up to 150 volts."

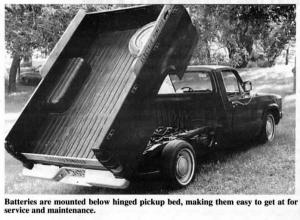

The truck is equipped with 20 Trojan 6-volt deep-cycle marine-type batteries wired in series. They weigh 71 lbs. apiece. Dozler hinged the bed of the truck and mounted the batteries below on a platform made from angle iron and steel plate. (Dozler beefed up the rear suspension with two extra leaf springs to handle the load.) The batteries drive a 9- in. dia., 18 in. long D.C. brush-type electric motor, which will operate in a 72 to 140-volt range. The motor mounts in the engine compartment along with two of the 6-volt batteries. The pickup's 12-volt battery remains in place in the engine compartment to power accessories and electric motor controls on the dashboard.

The pickup bed is raised and lowered with a 3-in. hydraulic cylinder off a Case 600 combine header and a pump off an IH Farmall that's driven by a GM starter motor. The design makes it easy to get at the batteries for service and maintenance, yet leaves pickup box free for hauling cargo.

The hardest part of the conversion was hooking up the electric motor to the bell housing on the pickup's 4-speed transmission, Dozler says. Because of where the motor was mounted, he needed to close a 2-in. gap between the motor and transmission. He ended up bolting a 24-in. sq. piece of 1/2-in. thick aluminum plate to three 18-in. sq. 1/2-in. thick aluminum plates. He then bolted the 24-in. sq. plate to the transmission and attached the smaller side to the electric motor.

Special gauges and meters mount on the dashboard to monitor the batteries, alternator and 12-volt battery. One box mounted below the dash allows Dozler instantly to check out voltage of each individual battery before and after a charge as well as under load.

Dozler says components like the ones he used, can be purchased from Electric Vehicles of America Inc. (P.O. Box 59, Maynard, Mass. 01754), for a total of about $5,000.

Contact: FARM SHOW Followup, Paul Dozler, 1967 Goodrich Loop, Denison, Iowa 51442 (ph 712 263-4510).

Click here to download page story appeared in.

Click here to read entire issue

Electric-Powered Farm Pickup ENERGY Alternative Fuels 19-5-27 "We were standing outside the hog house one morning this spring, visiting, when this vehicle just sneaked up alongside us. The only hint we had that anything at all was coming up the driveway was the sound of gravel crunching underneath the tires," says Delaine Listamann about his neighbor, Paul Dozler, whose pickup runs on electricity.

"It's really ingeniously designed," Listamann says. "It's out of this world."

Dozier, who farms near Denison, Iowa, says recent developments in electric power technology make converting cars, pickups - possibly tractors - more practical than ever.

"I was going to convert a car to run on electricity 10 years ago, but the technology then was `Stone Age' compared to now," he explains.

Dozler, who is a member of the Electric Auto Association (2710 St. Giles Lane, Mountain View, Calif. 94040), found a 1981 Ford Courier with a blown 4-cyl. engine. He bought the truck, which had more than 150,000 miles on it, for $500 from an area auto dealer. He started converting the truck last fall and had it on the road by spring, running 100% on electricity.

"It cruises along nicely at 55 mph and can do 65 mph or a little better," Dozier says. "But the faster you go, the less mileage you get out of a charge. Traveling at 40 to 45 mph, you can go 50 miles between charges. Recharging takes about six hours using a 110-volt charger that I stepped up to 150 volts."

The truck is equipped with 20 Trojan 6-volt deep-cycle marine-type batteries wired in series. They weigh 71 lbs. apiece. Dozier hinged the bed of the truck and mounted the batteries below on a platform made from angle iron and steel plate. (Dozier beefed up the rear suspension with two extra leaf springs to handle the load.) The batteries drive a 9- in. dia., 18 in. long D.C. brush-type electric motor, which will operate in a 72 to 140-volt range. The motor mounts in the engine compartment along with two of the 6-volt batteries. The pickup's 12-volt battery remains in place in the engine compartment to power accessories and electric motor controls on the dashboard.

The pickup bed is raised and lowered with a 3-in. hydraulic cylinder off a Case 600 combine header and a pump off an IH Farmall that's driven by a GM starter motor. The design makes it easy to get at the batteries for service and maintenance, yet leaves pickup box free for hauling cargo.

The hardest part of the conversion was hooking up the electric motor to the bell housing on the pickup's 4-speed transmission, Dozier says. Because of where the motor was mounted, he needed to close a 2-in. gap between the motor and transmission. He ended up bolting a 24-in. sq. piece of 1/2-in. thick aluminum plate to three 18-in. sq. 1/2-in. thick aluminum plates. He then bolted the 24-in. sq. plate to the transmission and attached the smaller side to the electric motor.

Special gauges and meters mount on the dashboard to monitor the batteries, alternator and 12-volt battery. One box mounted below the dash allows Dozler instantly to check out voltage of each individual battery before and after a charge as well as under load.

Dozier says components like the ones he used, can be purchased from Electric Vehicles of America Inc. (P.O. Box 59, Maynard, Mass. 01754), for a total of about $5,000.

Contact: FARM SHOW Followup, Paul Dozier, 1967 Goodrich Loop, Denison, Iowa 51442 (ph 712 263-4510).

To read the rest of this story, download this issue below or click

here to register with your account number.